Inspecting the calipers after a trackday I noticed a small brake fluid weep from 2 pistons. They had been installed for 2 and a half years and it appeared a refurb was in order.

Calipers removed. To remove the pistons an airline is used to blow the pistons out but a piece of wood is placed between the pistons to stop them shooting out and into each other.

This piston was sticking but the other 2 had moved straight away. I pushed the other 2 back into the caliper and wedged them in place with another piece of wood, that meant only the sticking piston was able to move. After several seconds it started to come out and eventually popped with a bang into the piece of wood.

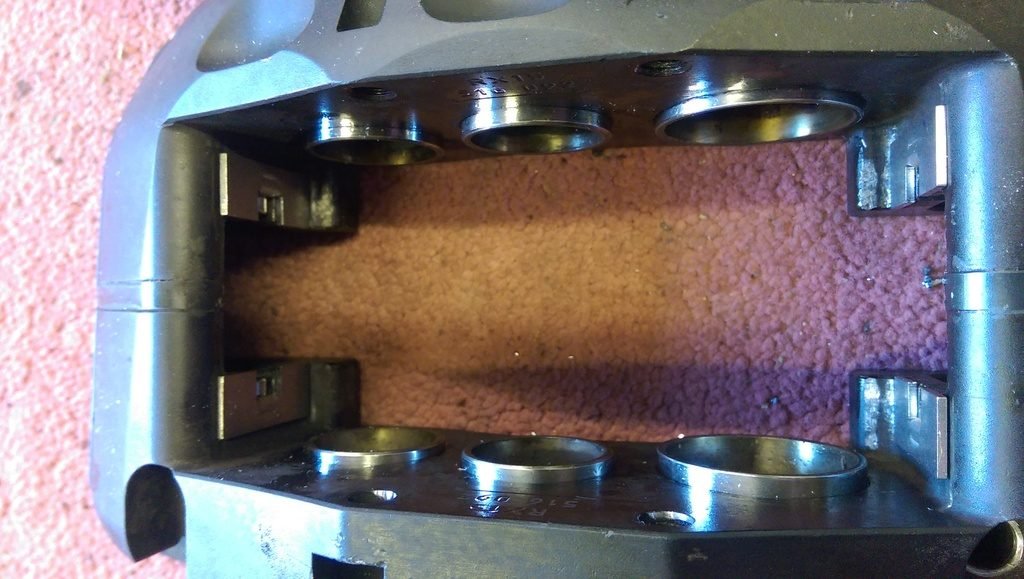

All the pistons are around halfway out of the caliper at this point.

By wiggling each piston with my fingers I was able to extract them from the caliper. Some were tighter than others but all could be removed by hand.

Next stage is to remove the old piston seals

I had a small length of aluminium bar that I filed to a point and used that to pry the seal out. Next time I`d just use a jewelers screwdriver and take care when removing them

Once the seals are released from the groove, it`s simple to lift them out

All seals removed

The pistons movement had worn a ridge on the seals

Pistons, Seals and Abutment plates all removed.

Bleed nipple unscrewed.

A long allen key was inserted into the bleed nipple hole

This passed into each piston chamber and ensured any debris in the caliper was removed

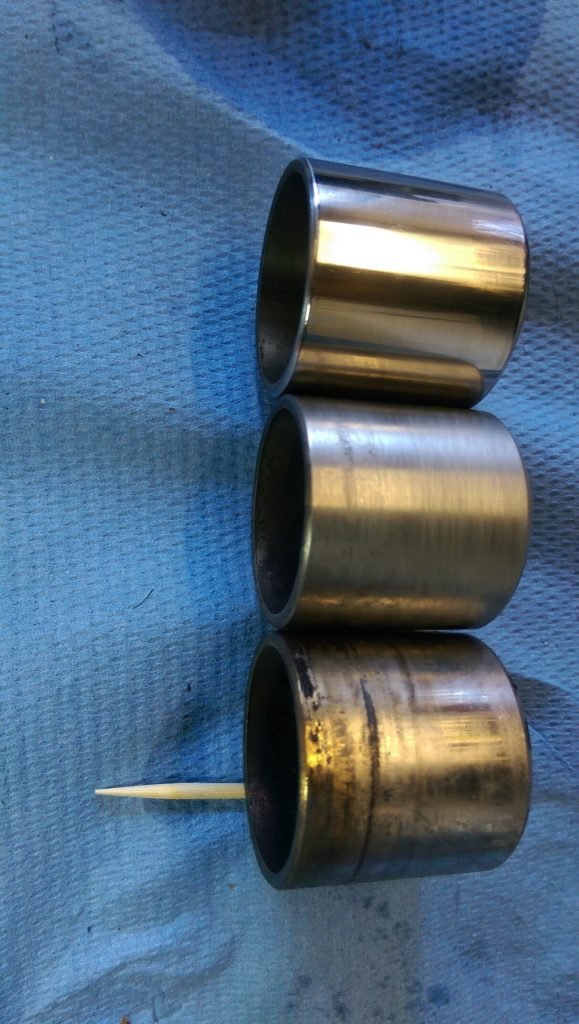

The Pistons were in a sorry state but had no nicks or marks on them

Initial cleaning was done with a cloth and some Brasso. A polishing wheel on a bench grinder would be FAR easier.

Before and after

There were still some marks I couldn`t remove so used some Micro Mesh 6000 Grit finishing paper to polish the Pistons.

Top – Polished

Middle – Cleaned with Brasso / Cloth

Bottom – Removed from Caliper.

Cleaned the seal recess with brake fluid and an old toothbrush

Finished off with a cotton bud

Clean and dried out with paper towel then blown clean.

Abutment plates were slightly distorted.

New set of plates and screws ready to fit.

Plates fitted.

Ready to reassemble. Cleaned Pistons, new seals and brake fluid for lubrication.

New seals inserted into the recess.

Pour some brake fluid into a container.

Smear brake fluid on the outside of the piston. This acts as a lubricant when refitting

Pistons pushed back into place. If they don`t push in easily by hand, then remove them, re-lubricate and try again. They should all slide in without any excessive force.

Caliper overhauled with new Seals, Abutment plates and cleaned pistons.