This is now being broken for parts. EVERYTHING available.

For Sale, my very heavily modified MK2 Golf trackcar.

I’ve owned this car since 2007 and have built it from a bare shell into the car you see listed here. It’s a 1990 3 door Golf MK2 CL, non sunroof, V5 is included.

I appreciate this will be a very long advert, but I want to answer as many potential questions as possible.

Whilst the car has been used on the road previously, I let the MOT expire at the end of April 2024 as I was only driving the car on track and there was no need to tax or insure it so I let the MOT lapse.

The car is quite well known in the trackday community and is most notably known for the laps around the Nurburgring. It is the fastest MK2 Golf ever to lap the Nurburgring with a quickest lap on video of 7:23 BTG.

I have posted several laps under 7:30 on my Youtube channel where you can find laps from most UK circuits along with the Nurburgring, Spa Francorchamps, Zolder and Zandvoort.

The car became very well recognised after featuring in this video with Misha Charoudin

In a straight line, the quickest I’ve achieved is a GPS 174.9MPH / 281.4 KPH, set on the Nurburgring.

It has also featured on Speedhunters with this article.

I’ll try and list everything I’ve done to the car over the years, the list is extremely comprehensive and many of the components have gone through several versions before I was happy with the final solution. Developing a car like this is always has a few issues along the way and I’ll list those, and the solutions I integrated below

Shell

The Shell is a 3 door, 1990 MK2 Golf CL. It is fitted with ‘Big Bumpers’ from the later model although these have been lightened with modified fixing methods.

Photos are as recent as possible, but some things like the engine and roll cage were taken during the build, installation and spraying to show more detail.

The bonnet is fibreglass with a reverse scoop to help remove engine bay heat. It is secured by 4 Aerocatch clips, the centre 2 are needed as the middle was lifting above 130mph.

Front wings are fibreglass with integrated flare to help exhaust heat and high pressure from the wheelarch and larger wheelarches to cover the 17″ wheels

Roof is original, with the addition of a fibreglass roof-scoop to add much needed cool air to the cabin whilst on circuit.

Doors are the standard steel frames, although heavily lightened. The internal steel skin has been removed and replaced with lightweight plastic to meet track day regulations, allowing you to wear a T-shirt.

Rear quarters are original, but the arches have been modified to fit the 17″ wheels

Tailgate is original but again heavily lightened with removal of most of the inner skin, still retaining the original latch and gas struts. The rear wiper has been removed and smoothed.

The addition of lifting tubes making jacking simple but the rear tubes are for balancing on jackstands rather than lifting that car as I was unable to tie them into the cage.

Roll Cage

The shell has been extensively strengthened by the addition of a multipoint weld-in cage which is tied to the shell by windscreen gussets tieing the A pillar to the windscreen surround, the B pillar, and bar at floor level joining the B hoop feet are also gussetted to the shell.

The front bars pass through the bulkhead to the front turrets, bulkhead and rear turrets with a harness bar and door X bars for side impact protection following MSA guidelines of spreader plate 3mm thickness and size along with seamless CDS tube.

As the front tubes have a double bend, the required straight bar has been added for MSA compliance.

Chassis Legs

The front bulkhead started cracking many years ago, the damaged area was removed and a bar was welded across the bulkhead linking the chassis legs together.

Fitting the current gearbox, which I’ll go into detail later, required modification of the nearside chassis leg to increase strength and allow the installation of a gearbox mount to the chassis.

After welding this was taken back to bare metal and resprayed.

Seats

Seat rails are welded to 3mm spreader plates.

Seats are Cobra Sebring Pro-Fit with Schroth Profi-ii 6-point harnesses, drivers is 2×2 hans compatible and passenger is 3″

The passenger seat is as low and far back as possible, a spare bolster cushion is secured to the side of the raised gear shift tower to protect passengers knees, a duplicate is fitted for the driver.

A strong Aluminium footrest is also installed for passenger comfort.

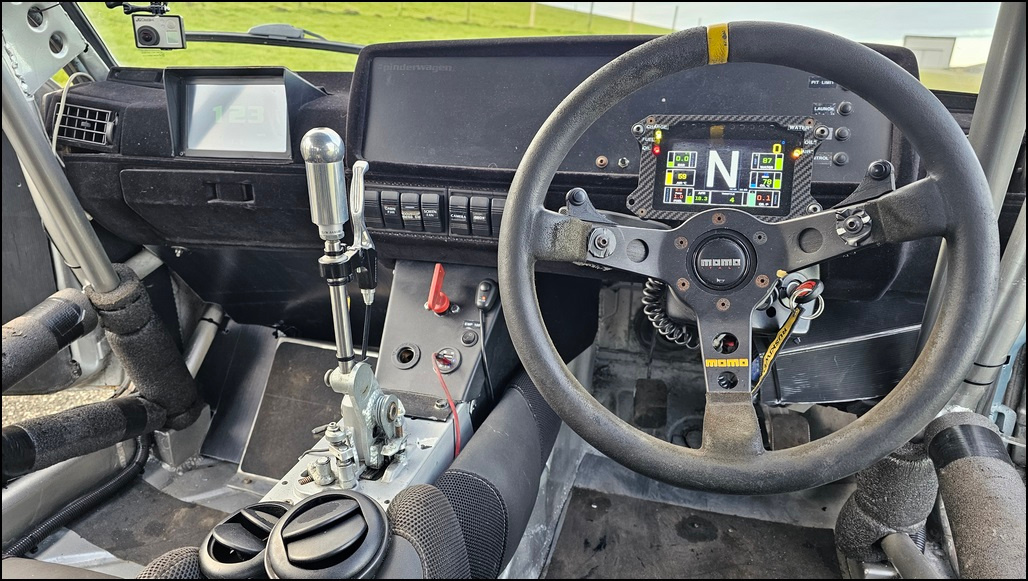

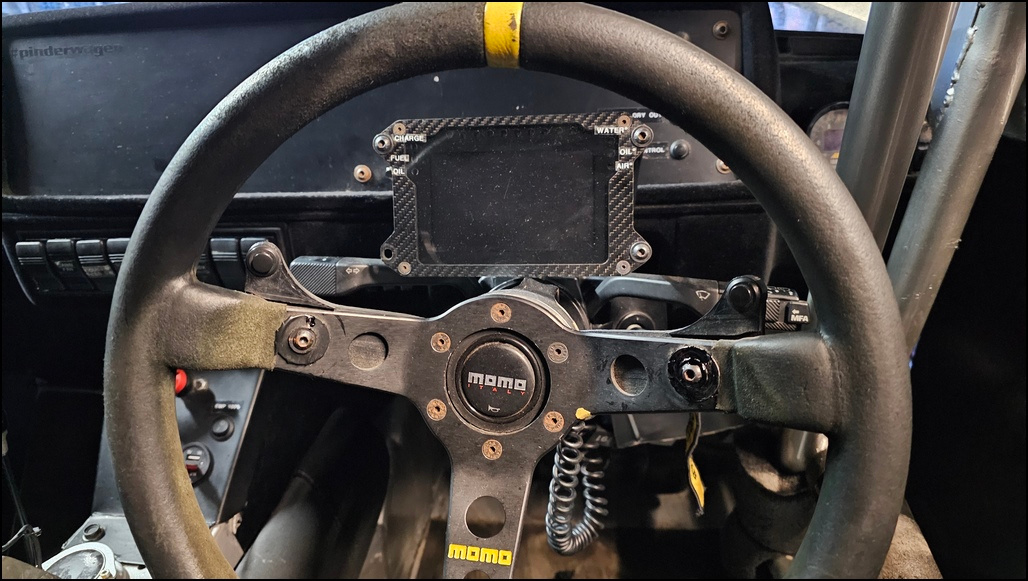

The dashboard is a standard MK2 Dash but it has been flocked to reduce glare. The original steering column switchgear is retained but the instrument cluster has been replaced with a Digital dashboard showing not only speed and RPM, but many other engine parameters. The dash can be customised to show anything available on the CANbus.

The ‘passenger dash’ is a second display recessed into the dashboard in front of the passenger which shows GPS speed as well as a throttle, rpm and boost.

The 12V Battery isolator / ECU cutout along with other ancillary switches mounted centrally are easily accessible whilst strapped into the car.

Driver cooling is from the roof mounted roof scoop and also from 2 x inline 12V fans that take air from the factory vents behind the rear bumper then blow via centre mounted adjustable face vents to the driver and passenger, from experience on hot days, these are extremely welcome when sat in the car waiting to join / leave the track.

Engine

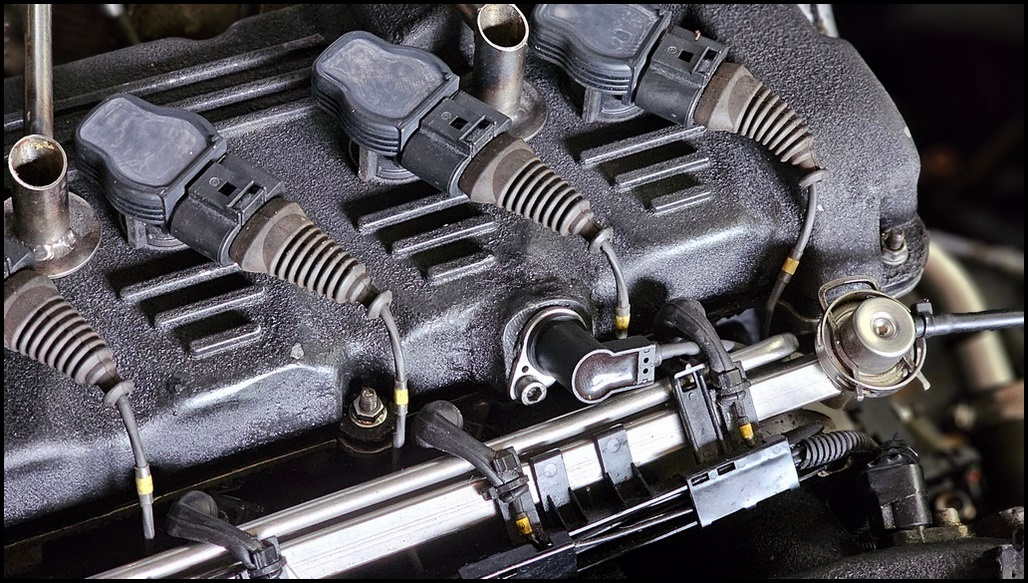

The engine is a VW 2.0 16V ABF, fitted to the MK3 Golf.

It was rebuilt in late 2023 with all new bearings and piston rings into a freshly bored/honed block. The crankshaft is a standard forged ABF crank with internal trigger wheel.

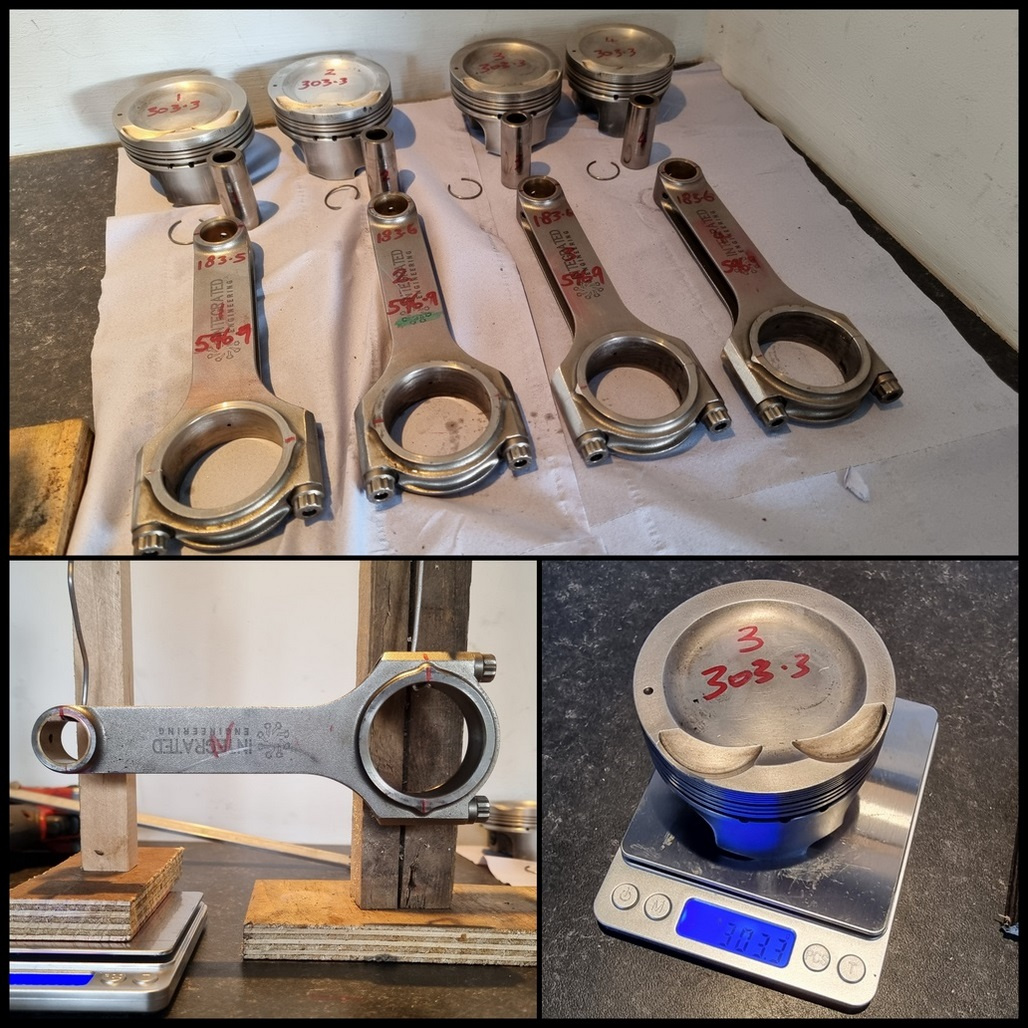

The Block is overbored to 83mm giving an increased capacity of 2008cc, this is fitted with balanced Wiseco 8.5:1 Forged pistons. The conrods are Integrated Engineering rifle drilled, using genuine ARP rod bolts.

All rods and pistons were balanced to within 0.1g.

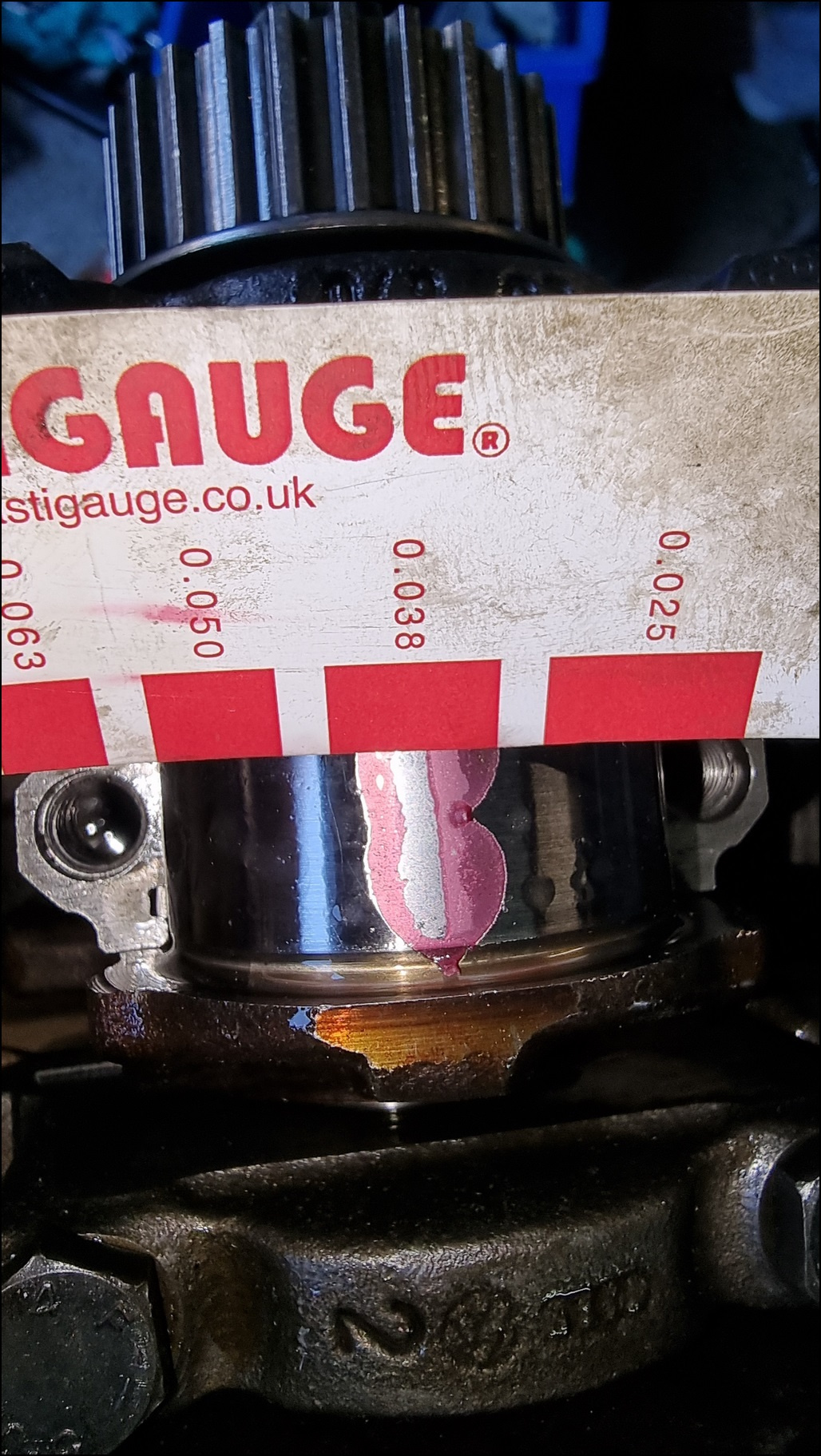

New Glyco Main and big end bearings were fitted and tolerances checked with plastigauge

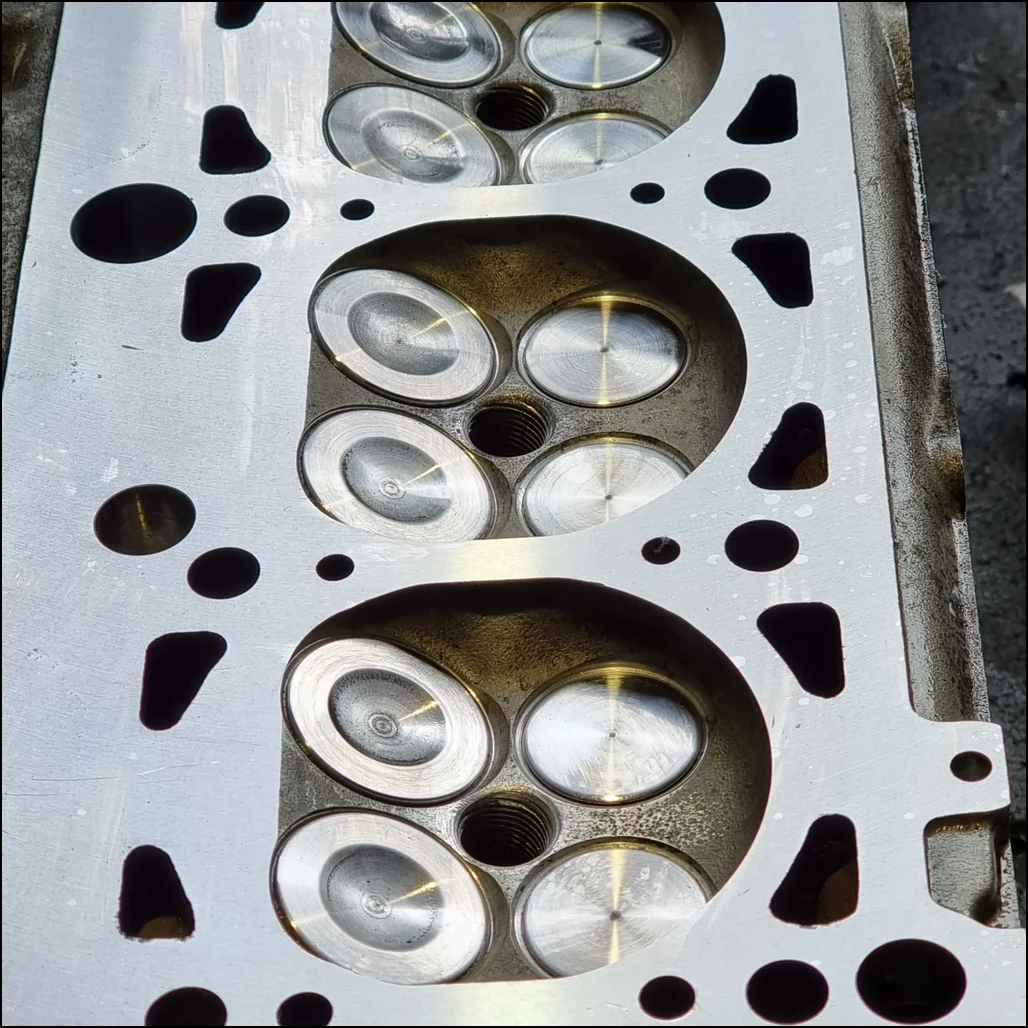

The Cylinder head has had a minimum skim for flatness at the same time as the block was decked, again a minimum to ensure the best possible seal. All stem seals were replaced. Camshafts are original ABF cams with hydraulic self-adjusting tappets.

The headbolts are genuine ARP studs and bolts.

Over the years, I experienced several engine failures due to oil starvation on fast left-hand corners. To address this, the sump was baffled with internal hinged doors, and the oil fill amount was slightly increased to account for the coolers, which provided some improvement. However, the addition of an Accusump made a significant difference. As long as the Accusump is charged and the oil level is checked and maintained regularly, I haven’t experienced a failure since.

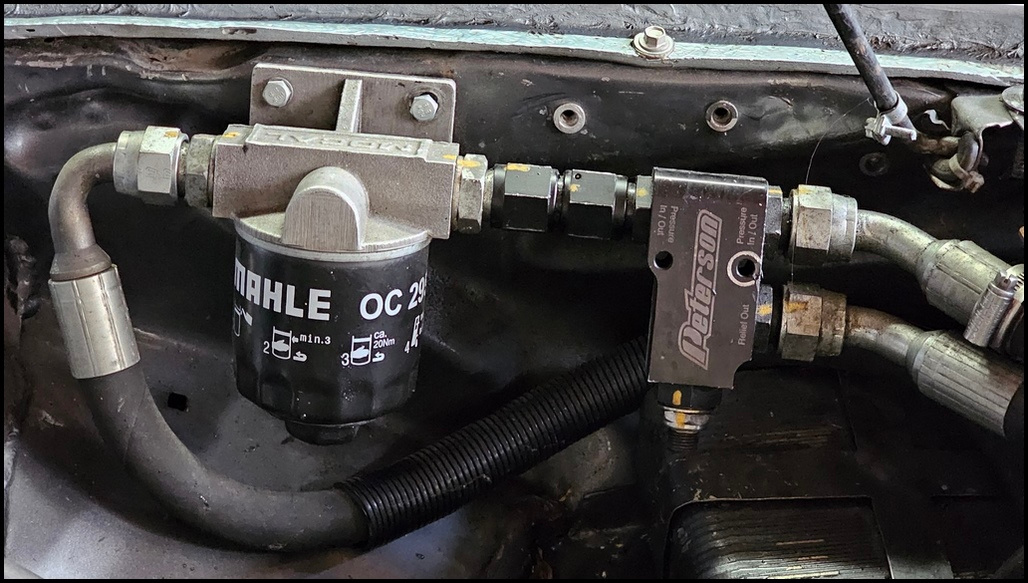

A failure of the stock oil pump’s internal relief valve highlighted a weak point. To address this, I modified the oil pump to block off the internal relief valve. I then plumbed in a Peterson external relief valve with relief to the sump. The Peterson valve allows you to set a defined peak oil pressure, which I have set to approximately 5.25–6 bar (compared to the OEM 4 bar). This higher oil pressure ensures the engine is sufficiently lubricated and the Accusump gains a stronger oil charge, and therefore providing a more effective discharge when required.

Whilst fitting the Peterson, I opted to do an oil filter relocation to the inner wing to enable me to easily change it when required.

A detailed write up of how I have plumbed the accusump is available here, however missing from that diagram is the turbo feed, previously this was from the head, however the littco turbo failed from an oil supply issue, I have since moved the feed to the oil filter housing via a Turbosmart inline pressure regulator and filter to ensure the Turbo sees a controlled 40psi.

The alternator is fitted with an underdrive pulley for longevity at high RPM.

Turbo

What sets this apart from other MK2’s is the turbocharger setup.

It’s a new, Genuine Garrett G25-660 Turbo that was fitted under 200miles ago. The heatshield is to project the outlet silicone joiner.

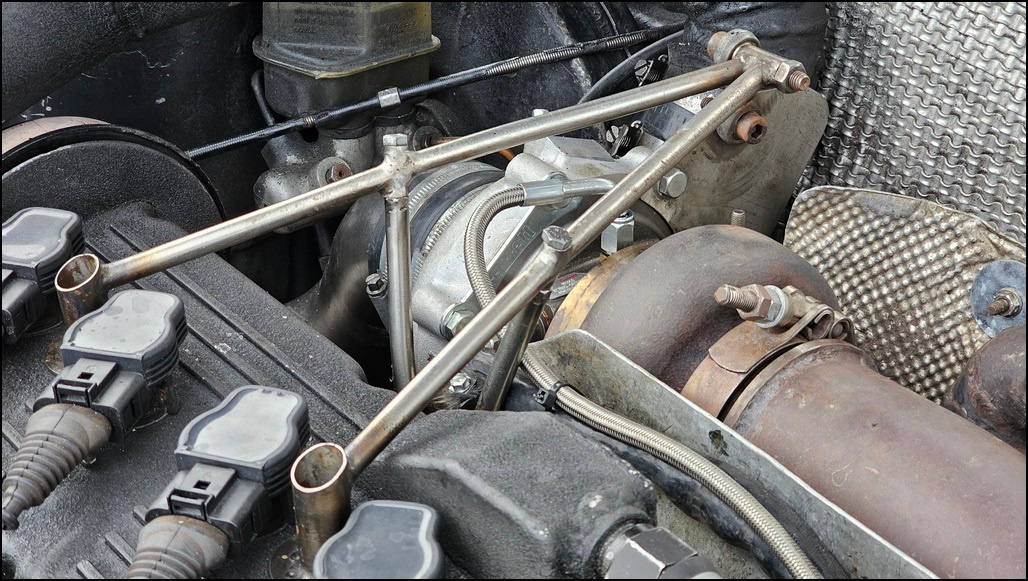

The custom tubular stainless steel exhaust manifold with V band for turbo and the TiAL MV-S with 0.8Bar spring external wastegate.

High frequency vibrations caused fractures in the previous exhaust manifold, but the addition of the tubular brace completely addressed this problem.

The exhaust system is 3.5″ from the turbo to the downpipe where is connects via male/female V Band. The wastegate is connected via a twin wall slip joint.

The downpipe contains the wideband lambda sensor and flexible connection, then another V band to the 28″ silencer that runs along the centre tunnel. This again connects to a V band before going over the rear beam to the rear oval silencer and tailpipe

The system is all 3″ stainless and passes every noise test in the UK, including Bedford driveby . Thruxton has a 90dB static test and this only passess if the front silencer is repacked prior to a visit, the heat from the turbo degrades the wadding in the front silencer over time reducing its effectiveness. This is only an issue passing Thruxton’s test, every other 98dB test is passed easily.

Every V band is accessible from under the car and each part of the exhaust can be easily removed and replaced independently.

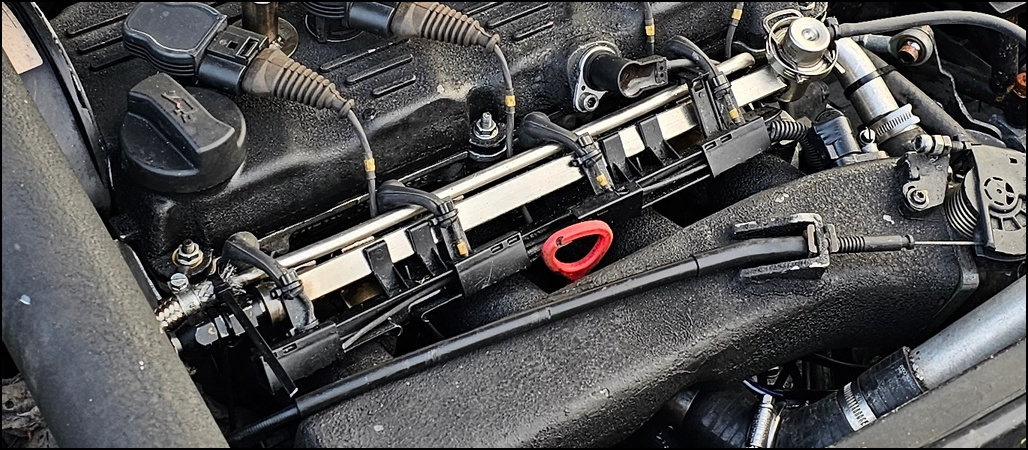

Injectors are Bosch 900’s but with a 4Bar FPR are rated to 1000cc and peak around 70% duty cycle at when the turbo was run at 2bar boost. The fuel system is a swirl pot fed from the intank pump, then via underbody AN6 Teflon lines through an 044 pump to a modified 1.8T fuel rail

The intercooler is a 600 x 300 x 76 high efficiency Toyosport core with 3″ Aluminium elbows welded to it. The Turbo to intercooler hardpipes are 2.5″ and intercooler to Throttle body are 3″ hardpipes.

After several silicone hose failures over the years I replaces as many as possible with Aluminium pipes and only have straight silicone joiners. Since this modification I haven’t had a single issue.

I run Fuchs Titan Pro S 5W50 Oil, cooling is a large Setrab 52-12864-01 Proline cooler mounted which ensure oil temps are well under control and even following another car closely.

Water cooling is via a triple pass 50mm thick Aluminium radiator that could do with replacing within the next couple of years. I had stones damage a few of the bars and had to weld those up in the end tank which meant reducing the available cooling capacity. This was several years ago but it’s just something on my list of nice-to-haves.

The original belt driven waterpump and integral thermostat has been replaced with a Davies Craig 150l/min electric water pump. This is controlled via the ECU to ensure quick warm-up but also can be run at 100% by a dash mounted override button that runs the pump at 100% and the fans simultaneously to allow cooling even if you have to stop without time for a proper cooldown (in the case of a red flag without a cooldown lap for instance)

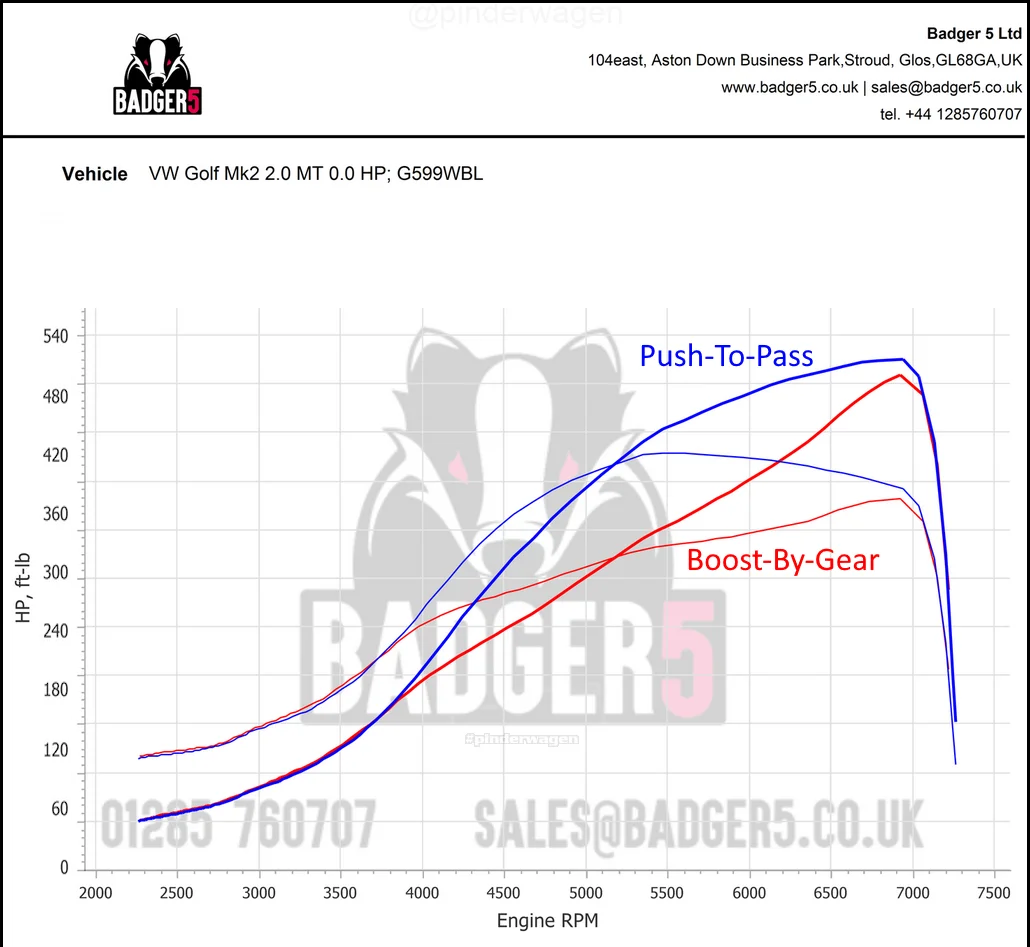

The boost control mapping offers 3 different power levels accessible from the steering wheel. Actuator pressure is 0.8Bar and around 370BHP, delivered very linearly.

The right steering wheel button switches to ‘boost-by-gear’, this is explained in more detail here https://pinderwagen.com/trip-reports/dyno-mapping-part-3/ although since then the turbo has replaced by a G25-660 which simply gives more power in each gear, but the power and torque curves are very similar.

The left button overrides the medium Boost-by-gear and switches to high boost. this is a more aggressive map which gives over 500HP in 6th, it is still Boost-by-gear but with much more midrange. Leaving this latched is possible but the midrange torque simply overwhelms the front tyres causing excessive tyre wear for little gain. It’s much easier to drive with the normal Boost-by-gear an then press high boost when desired.

The DTA S80Pro ECU controlled Map switch buttons are on the steering wheel and the traction control, launch control and pit limiter buttons are behind the digital dash.

A problem with the clutch master cylinder on the dyno meant the coast-down calculation was incorrect and the final figure of 520HP is approximate (the drag from the gearbox gave us a figure of 600+ which was incorrect, but the shape of the graphs are accurate)

As the ABF isn’t turbocharged from the factory, a required baffle chamber is welded to the rocker cover which breathes via a centrifugal separator, this vents to a multi chamber breather. They both drain to the sump and vent to the pre-turbo 3″ stainless inlet pipework.

Ignition was a problem, wasted spark kept blowing out on hot days over 1.7 Bar, so I fitted Coil-On-Plug after modifying the rocker cover. Since doing this there is no issue with high boost spark, although if the battery is very low, the car will crank but won’t fire every rotation. This was only an issue during initial testing or if the car is left with the EWP running for a long time and the battery runs particularly low.

I added a camshaft position sensor to the rocker cover which reads off the inlet lobe on cylinder 3. This has proven to be very reliable.

Gearbox

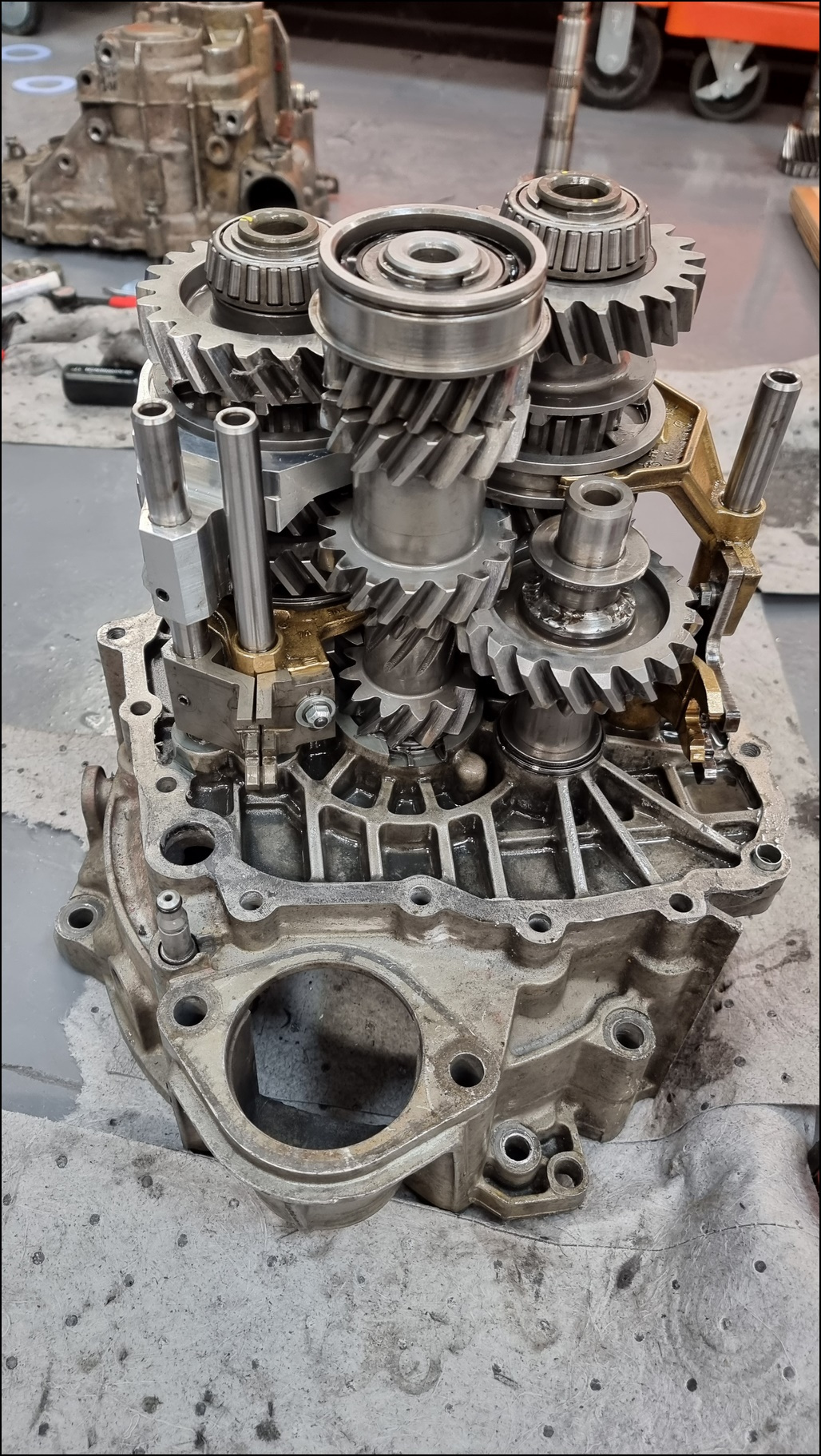

The Gearbox is an 02Q with SQS 1-6 Dog gearset and SQS Plate differential along with the billet shifter to selector fork parts.

One of the very last things I added was to fit an SQS-E Sequential shifter. It is still a H-Pattern gearbox, the shifter has a strain gauge gearknob and gear position sensor. This is linked to the Ecu and allows full throttle flat-shifts with almost no loss in boost. It is absolutely superb on track and after many hours is now setup to work without issue. Extra heatshielding was required for the shift cables, or they would get hot on track, expand and cause mis-shifts. On part throttle I still lift the accelerator and use the clutch, downshifts require manual Heel and Toe.

The shifter requires a forceful pull or push to ensure the gearbox fully changes gear. It can take new drivers a while to get used to this, but being too gentle is a bad thing and you can end up stuck between gears and damage the dogs on the gear.

The gearbox tuns 75W140 oil and when cold makes it difficult to engage gear smoothly. I fitted a plate heat exchanger into the gearbox cooling pump system which allows the gearbox oil to be circulated and warmed whilst the car is stationary, by doing this I am able to warm the gearbox before taking it on circuit. The plate diff does cause an increase in gearbox temperature and the air-oil coolers ensure this is kept within tolerance.

The driveshafts and external CV Joints were a weakpoint and were upgraded to custom billet Satchel Engineering ones and I haven’t had a failure since they were fitted.

This 7:24 is with the current gearbox but traffic means it’s not the quickest I’ve done, however it shows how good the gearbox is.

Suspension

The dampers are custom valved KW Clubsort with Eibach ERS Springs, raised topmouts , Roll centre correction and Bumpsteer correction . Steering assistance is via a hydro-electric cabin mounted pump which gives good steering feedback, the fluid is fed through a cooler as it runs too hot on slicks without one.

Wheels

Running 17″ Team Dynamics Pro Race 1.2’s meant all the above modfications were necessary. The car currently sits on 245/40R17 AR-1 which have done less than 400 Miles. Front wheels are 8J

Rears are 9J.

A second set of 8J Team Dynamics Pro Race 1.2 are fitted with 225/45R17 Michelin PS4

a 3rd Set of 8J Team Dynamics Pro Race 1.2 are fitted with 235/610R17 Dunlop slicks

Finally, there are 2 x 8J Team Dynamics Pro Race 1.2 with 245/40R17 A052`s

Front Brakes are huge, 364 x 36MM AP rotors on custom Aluminium Bells. AP Pro5000 CP9660 6 piston calipers with Raybestos ST45 pads. A standalone UP28 vac pump is used to provide consistent vacuum assistance, taking from the plenum proved insuffucient after repeated hard braking, the vac didn’t have time to recover.

Rears are Golf MK4 Aluminium calipers, Polo 9N Stub axles with massively improved wheelbearings and EBC Yellowstuff rear pads on Polo rear discs with custom trigger wheel for the ECU traction control

Aero

The whole Aero package has gone through several versions, the front splitter with integram airdam that feeds the oil cooler and is 15mm Buffalo board with Aluminium airdam

The flat floor is vented in the centre to allow the exhaust to cool, otherwise cabin temperatures were unmanageable.

The fibreglass rear diffuser is connected to the floor and the Aluminium sideskirts tie it all together. The tailgate mounted rear wing is adjustable to stabilise the rear on high speed circuits.

Photos from 10th Jan 2025 showing the current condition of the car. The lightbar has been removed, this was only for the tracknight I attended.

Price

The car will be supplied as in the photos with a comprehensive parts package, including the following available to purchase.

- 10 x 17″ 8J Team Dynamics wheels and tyres as mentioned earlier

- 2 x lifting bars for jacking points.

- Engine block

- Crankshaft

- Cylinder head complete

- Front hubs with welded extenders

- Front wheel bearing

- Alternator

- CV Joints

- Brake pads

- Fuel tank lift pump

- Modified diesel starter motor (machined for better flywheel engagement on the ring gear)

There are numerous posts on this website and videos online showing the performance of the car and also listing the failures and fixes I’ve carried out over the years. If you expect to buy this car, drive it on track, put it on a trailer and only take it out for the next day without any inspection this isn’t the car for you. Whilst it has been reliable there are issues that crop up with a heavily modified car like this and I’m not going to pretend otherwise. What I have done is address every failure or issue I experienced and improve them to prevent recurrence.

As far as possible, everything has been built to allow disassembly with minimal tools, for example captive nuts are used extensively.

I’m not 24/7 support, however I will be available to answer questions to the buyer of the car, I appreciate me taking 5 minutes explaining how to remove something could save hours of headscratching.

The ‘negatives’ if you can call them that, are that if I was keeping the car my future modifications would be a rewire and installation of a PDM Module. Some of the loom is from 1990 and the engine / ecu loom has been modified over the years. I haven’t had any electrical issues but it’s one of those jobs that I know would be beneficial. The front wheels and tyres limit traction and tubbing the front wheel arches, fitting larger wheels and tyres is on my list. Replacing the radiator is not critical but it’s something that I would do at some point.

Throughout my ownership and this advert I have been honest and transparent. I’ve listed everything I can think of and will answer any questions you have about things I’ve forgotten to mention.

I will update the advert should questions be asked I didn’t think to include.

Collection preferred, UK and European delivery can be arranged if required.

Contact me via nige@pinderwagen.com or 07905136396.

- VW Golf MK2 G599 WBL

- Multipoint weld in cage

- Cobra Sebring XL Seats

- Schroth Profi ii 6 point 2″ HANS Harness

- Schroth Profi ii 6 point 3″ Harness

- Cabin ventillation from inline 12V high flow fa

- Chassis mounted side jacking points

- 2.0 16V ABF Engine

- Forged crank

- H Beam rifle drilled conrods

- Wiseco 83mm Forged 8.5:1 pistons

- ABF Head and cams

- Bosch 1000 injectors

- Modified fuel rail with 4bar FPR

- Triple pass radiator

- Lightened flywheel

- Uprated pressure plate and clutch

- Hydraulic clutch pedal

- Hydraulic concentric slave cylinder

- Baffled sump

- Setrab high efficiency oil cooler

- Accusump, controlled by ECU

- DTA S80Pro ECU

- DTA 5″ Digital dash

- ECU Controlled Boost by gear

- Steering wheel buttons for boost selection

- Traction control with wet / dry setup

- Garrett G25-660 Turbo

- Tial wastegate

- Large intercooler 3″ connections

- Custom stainless exhaust manifold

- Custom 3″ exhaust system

- 02M Gearbox with SQS Dog gearset

- SQS Plate differential

- SQS-E Sequential shifter

- Gearbox pump, filter and cooler

- Gearbox heat exchanger

- AP Pro 5000 CP9660 Front Calipers

- 364mm x 36mm front rotors

- Custom brake bells

- Custom brake brackets

- Braided brake lines front and rear

- Electrically powered vacuum pump for brake booster

- Custom valved KW Clubsport Dampers front and rear

- Eibach ERS Springs

- Custom front wishbones with additional track and caster

- Front wishbone and topmount all spherical bearings

- Front hubs with SKF repacked wheel bearings

- Balljoint extenders

- Roll centre correction

- Raised front turrets

- Rear beam with Polybushes

- Lowered rear damper mounts

- Polo 9N uprated rear stub axles and bearings

- Increased rear camber

- Electrically driven hydraulic power steering pump

- Golf MK3 power steering rack

- Solid steering rack mounts

- Front subframe modified for 02M clearance

- Custom lower brace

- Engine lower brace modified for custom front engine mount

- Custom rear engine mount

- Custom gearbox mount

- Custom gearbox to subframe lower mount

- Custom front splitter

- Custom flat floot

- Custom sideskirts

- Custom diffuser

- Custom rear wing

- Fibreglass widened front wings

- Fibreglass vented bonnet

- Fibreglass roof scoop

- Polycarbonate side and rear windows