Standard front wheel bearings are fine for road use but can often fail when put under the loads of a track car. The increased temperatures can cause the standard grease to break down and the bearing fails shortly afterwards.

My front wheel bearings were failing after a few months due to the loads and heat from the brake system. I use Genuine SKF bearings but the grease was the issue.

By stripping the bearing, removing the old grease and repacking with an uprated grease the bearings have lasted 2 years and are still going strong. A very worthwhile modification in my experience.

I use SKF VKBA 1358 front bearings but I believe any SKF wheel bearing can be stripped the same way.

Bearing, Grease, Sharp blade, Small screwdriver, Thinners, a tub and soft brush.

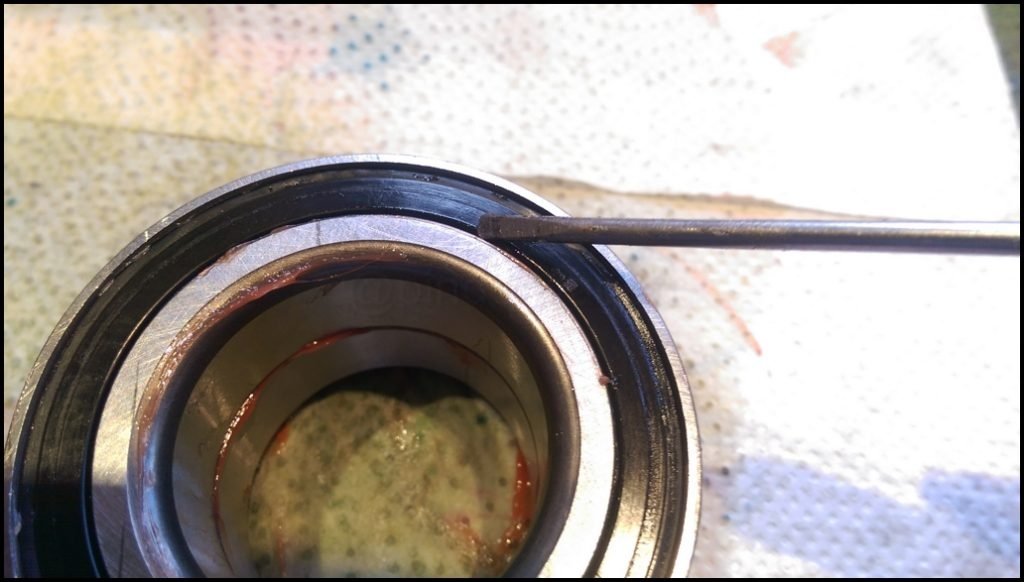

Slide the blade vertically between the edge of the seal and the external housing

Carefully lay the blade flat to lift the outside lip of the seal. Don`t push it in too far, you want to remove the outer seal and not touch the inner one at this point.

Slide a thin screwdriver into the gap and gently prise the seal upwards

Push the screwdriver under the seal and lift. You can see the lip seal coming away from the inner race.

The outer seal ready for removal

Outer seal removed and placed to one side

Next to be removed is the inner seal

Taking care not to damage the lip seal, insert the thin screwdriver between the inner race and the seal

Lay the screwdriver flat and the seal pops out

Remove the seal exposing the bearing cage and balls

Place the seal to one side

Use 2 fingers into the centre of the inner race and push outwards

Whilst applying outwards force simply lift out the inner race

Inner race removed

One inner race, cage and balls removed.

Flip over the bearing and repeat the above procedure to fully strip the bearing

Lift off the cage and balls from the inner race

Wipe off excess grease

Clean the inner and outer race with thinners and a soft brush

Clean the bearings and race with a brush and thinners or similar solvent

You can unclip each ball from the cage, clean the cage and ball and refit them.

I did that on one bearing then tried another without removing the balls. I removed the balls afterwards to inspect and there was no grease left in the cage so I don`t bother removing them when cleaning now as it makes no difference.

I use Redline CV2 grease on my wheel bearings and CV Joints. This has a higher temperature rating than standard and is suitable for bearings and CV`s.

Pack the bearings with grease, pushing it into the ball and cage area

Ensure all the surfaces are coated

Hold the inner race between 2 fingers again

The lower into the inner race

DO NOT OVERGREASE THE BEARING. Packing it tightly with a load of grease is not a good thing and it will over pressurise when the grease is hot.

Just look back at the original grease as it came from SKF, they don`t pack it tightly with grease and neither should you.

Clip the inner shield back into place

The outer cover is then replaced

Flip over the bearing

Refit the other half and then fit the seal

To ensure the inside and outside lip seals are in place lay the screwdriver flat and with gentle pressure on the seal rotate the bearing. This pushes the seal into the groove in the outer race. This isn`t always needed but I do it just to be sure.

If you aren`t fitting it straight away put it back in the bag and then you have a repacked bearing ready to fit when needed.