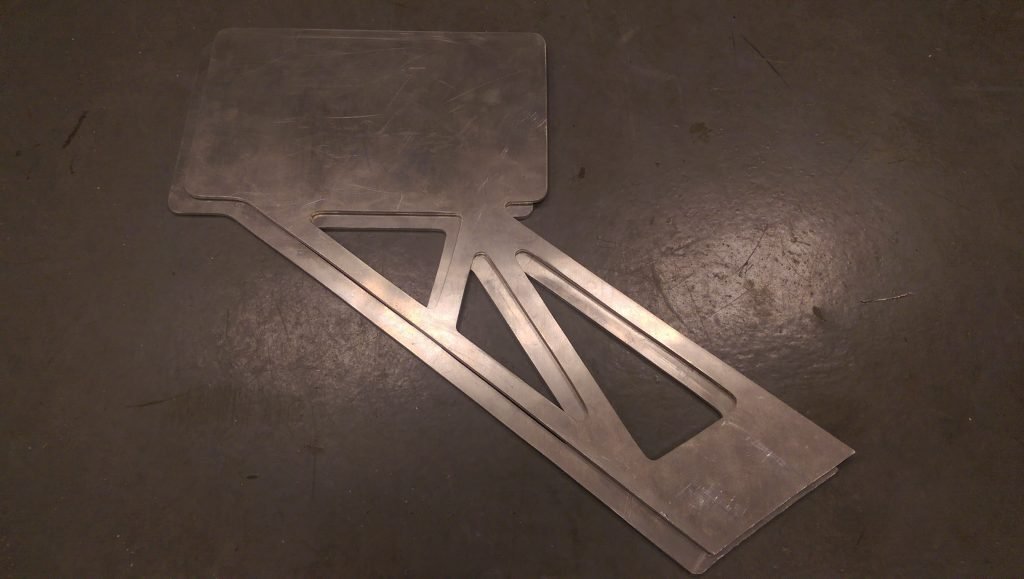

I wanted to move the rear wing rearwards and up into the clearer airflow. Previous supports were 3mm Aluminium but I increased the size to 4mm as I wanted them to be stronger due to the increased leverage from the longer supports.

The new wing location isn`t to give more rear grip, but hopefully by being in cleaner air it can be run at less of an angle and still give similar results due to them being more effective when mounted in cleaner air.

I made a template out of the black plastic I use for the door cards and when pressing on it to simulate load, the single rear stay bent first so I added the extra diagonal to triangulate it better. Not exactly cutting edge stress analysis but enough to see what bent first

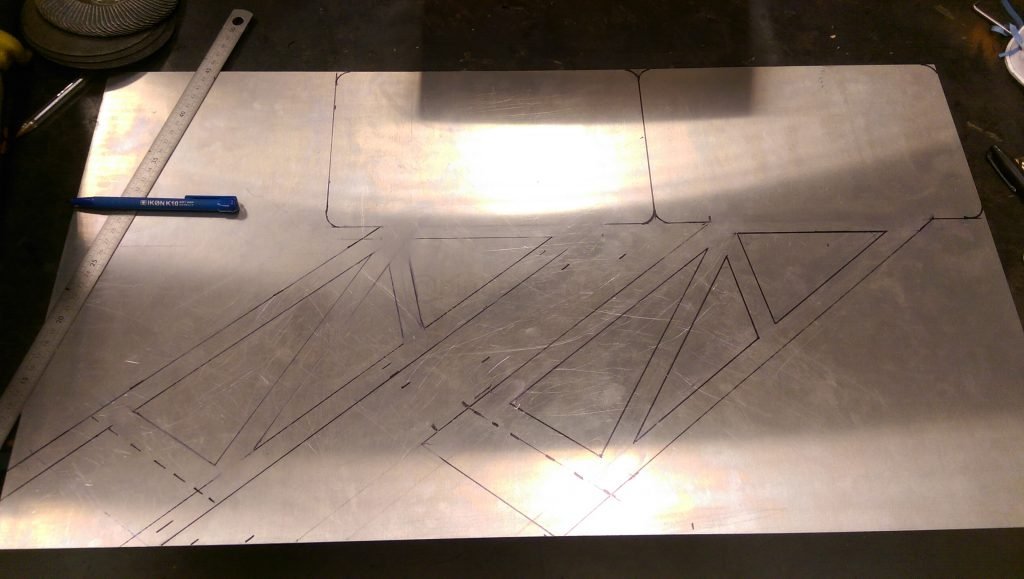

Draw outline onto 4mm plate

Duplicate outline for 2nd support

Using a washer, position so it just touches the 2 lines and draw around the internal hole. This allows marking of the centre of the hole to be drilled to make the internal corner a radius instead of a sharp angle.

Centre punch the middle of the circle

Pilot drill every hole

Drill with larger bit to just touch straight lines

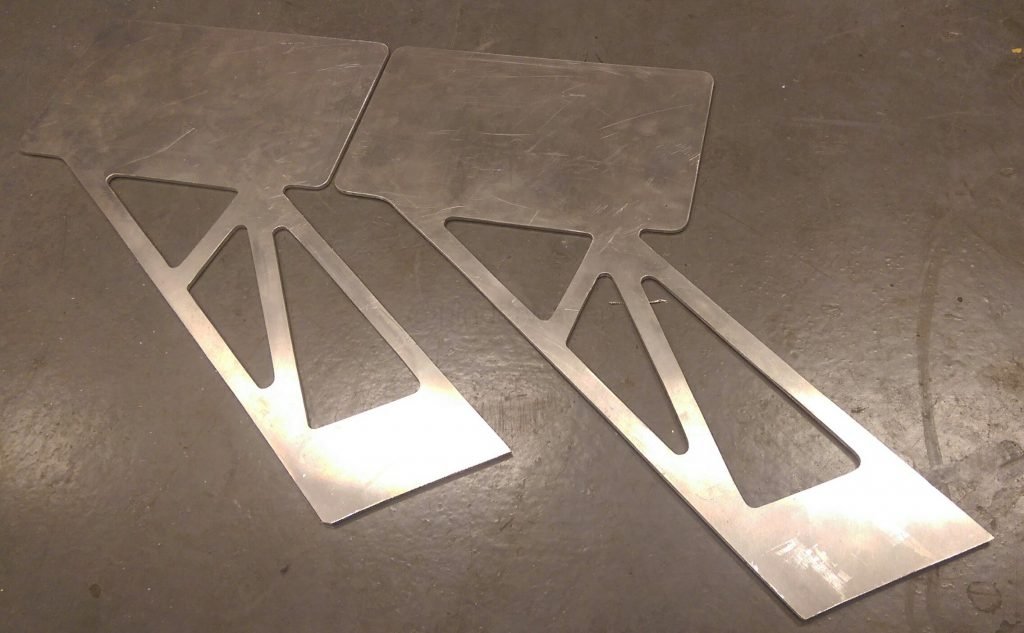

Cut out internal triangles using angle grinder and 1mm cutting disc

Use various flat and round files then emery paper to smooth the cut edges

Repeat for the 2nd support

Lay supports over each other to confirm both are the same

Move one slightly just to check both are identical

Bend ends that will bolt to rear tailgate and spray in etch primer after preparation

Spray Matt Black and mount.