# An update #

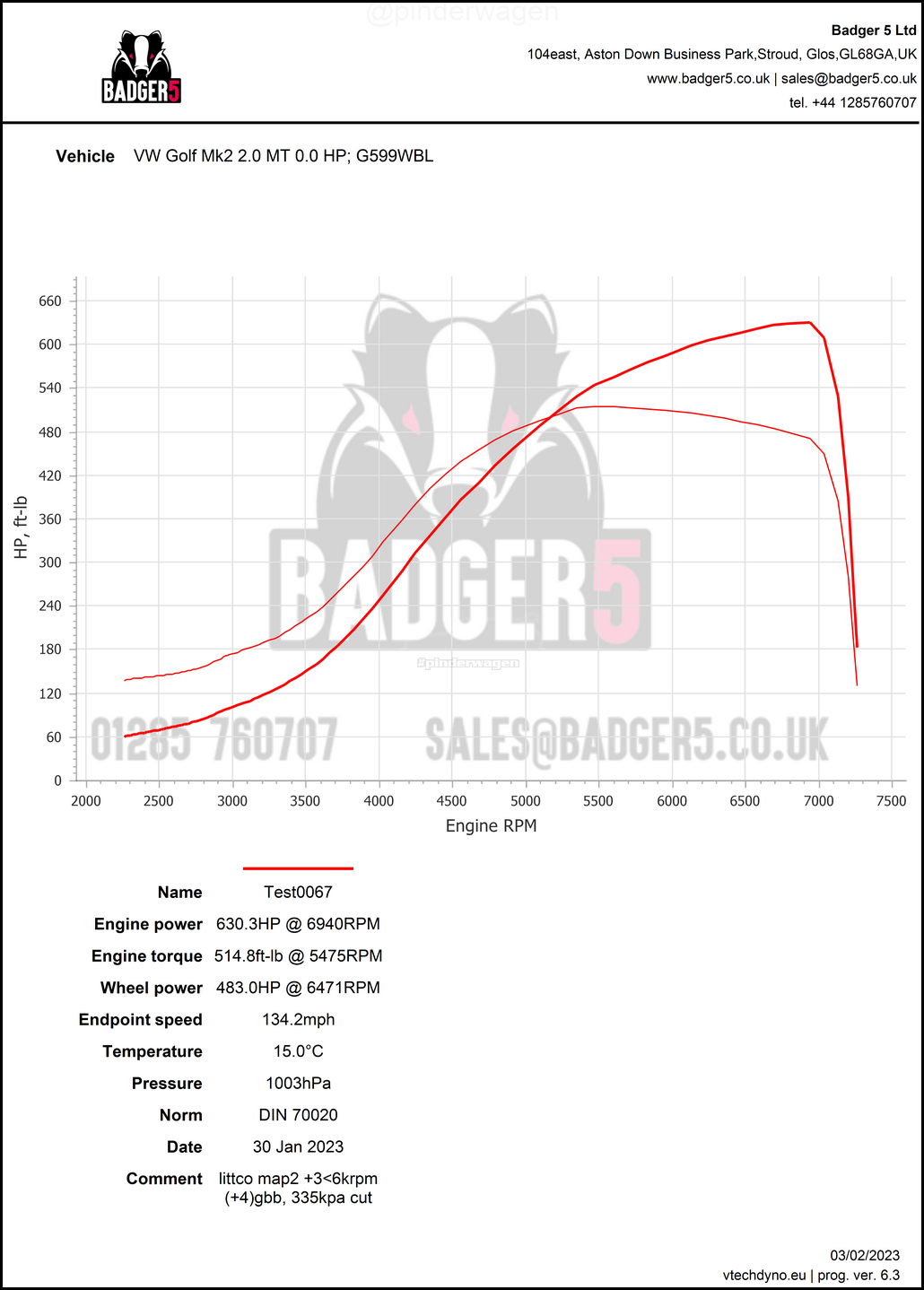

Following on from this dyno session, Bill had another car on the dyno with the same Turbo. They found inconsistencies with my data and realised the clutch wasn`t fully disengaging on the coastdown. The WHP values are correct, but the calculated Flywheel figures aren`t due to clutch drag on coastdown.

Usually the gearbox would be put into neutral after the pull but the Sequential shifter doesn`t allow that.

Rather than 630HP, a more realistic Flywheel figure is 560-570HP with 483WHP.

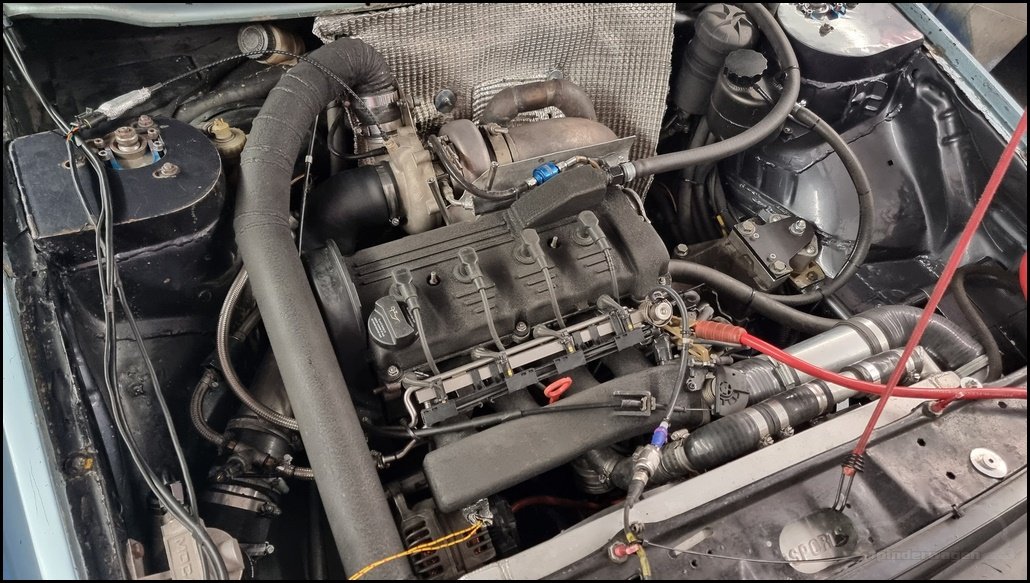

A quick recap of what I did since the car was last on the Dyno with the G25-660.

- I rebuilt the engine last year after a cylinder head crack caused water to enter the bore and it cracked the lining of Cylinder 1.

- A spare block was used and new head bolts.

- The Crankshaft, Rods and Pistons were the same, the new cylinder head had new guides and the exhaust valves swapped over.

- I then replaced the Turbo outlet elbow to be 3.5″ instead of 3″ to reduce post turbine pressure.

- New Stainless steel SCH40 1.5″ diameter exhaust manifold. Old one was 1.5″ diameter but Mild Steel and cracked/repaired in several places.

- Turbo to intercooler line remade in 2.5″ aluminium instead of 2.25″

- New Toyosports Intercooler.

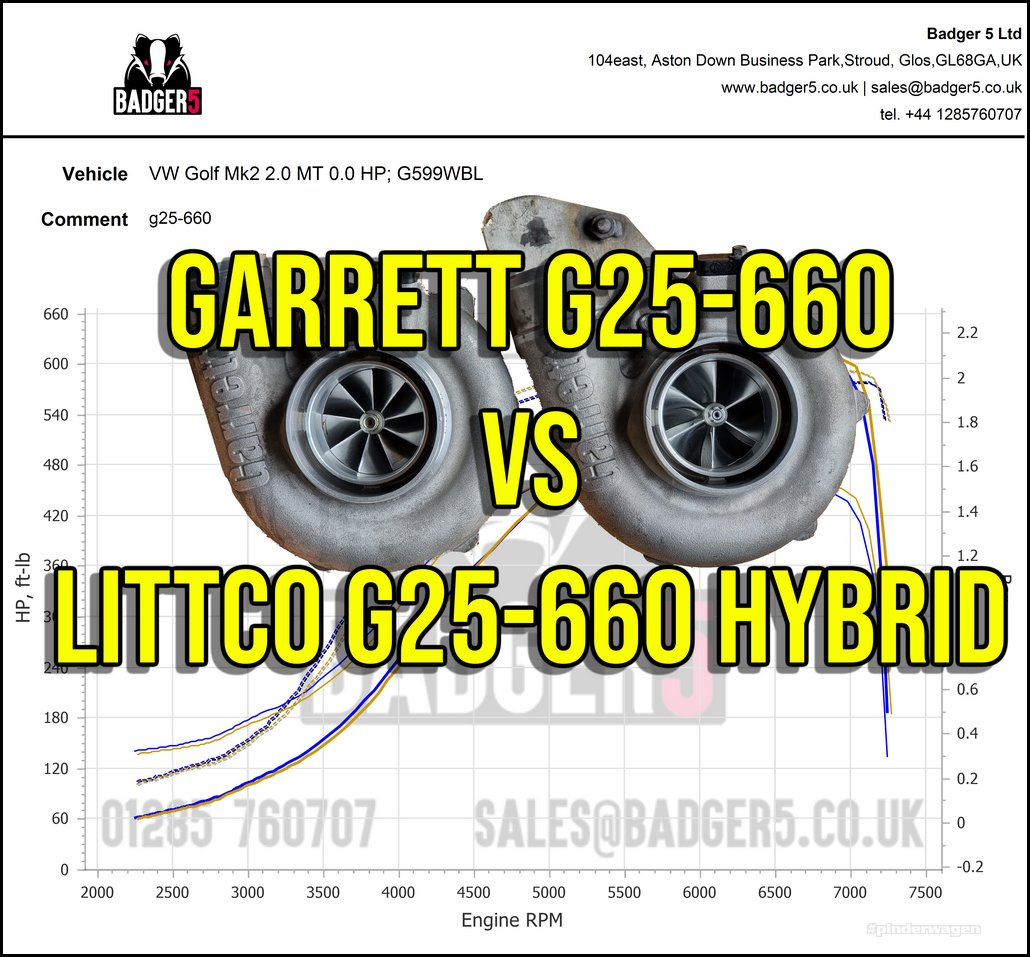

Littco have designed a G25-660 “Hybrid” which has different compressor and turbines compared to the Garrett. I was keen to test it out and the hope was that it would maintain high rpm high boost torque where the Garrett starting running out of steam.

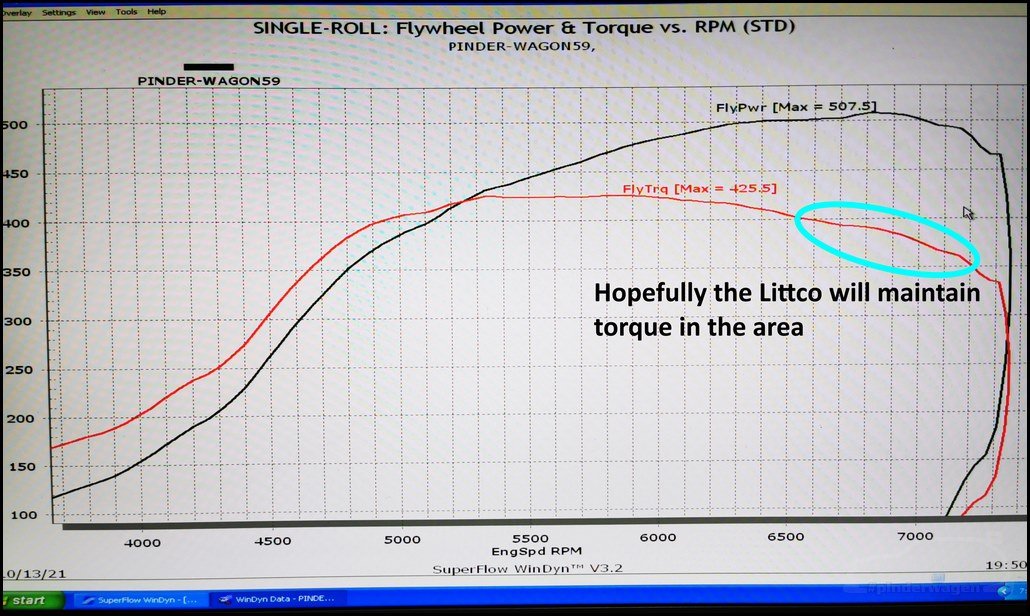

The area highlighted from 6500rpm to the limiter drops away from 400 ft-lb to 350 ft-lb. It`s still plenty but could be felt when driving. Whilst I don`t expect the Littco to be able to maintain the torque as a flat line, that’s simply unrealistic, what I do hope is that we can reduce the amount of drop off.

Having both turbos complete and ready to fit gave me an opportunity to do some proper back to back testing !

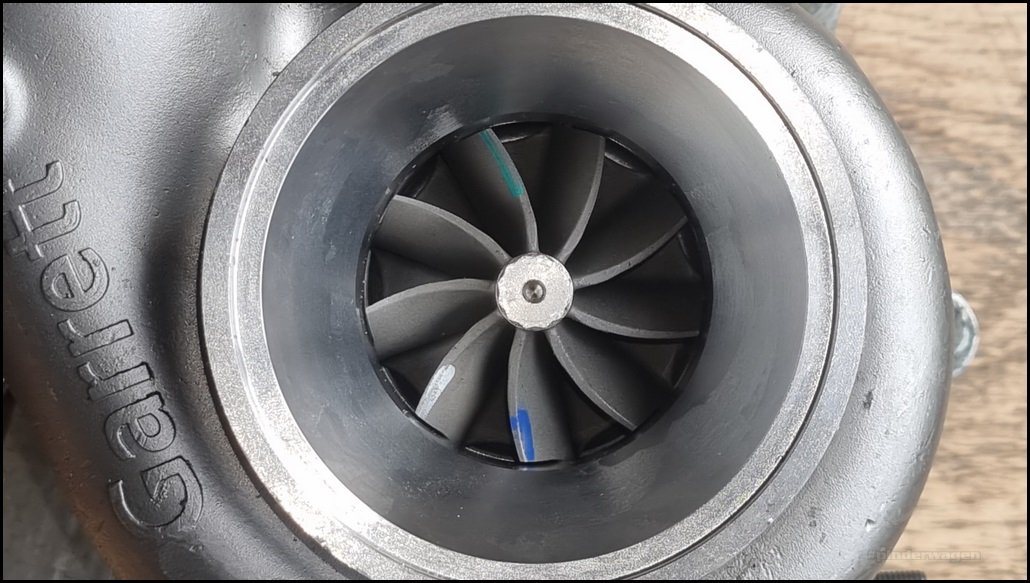

Garrett Compressor

Littco Compressor, much taller but the same overall diameter exducer and 57mm inducer vs 55mm Garrett.

Garrett Turbine

Littco Turbine is 3mm larger diameter requiring some machining of the exhaust housing.

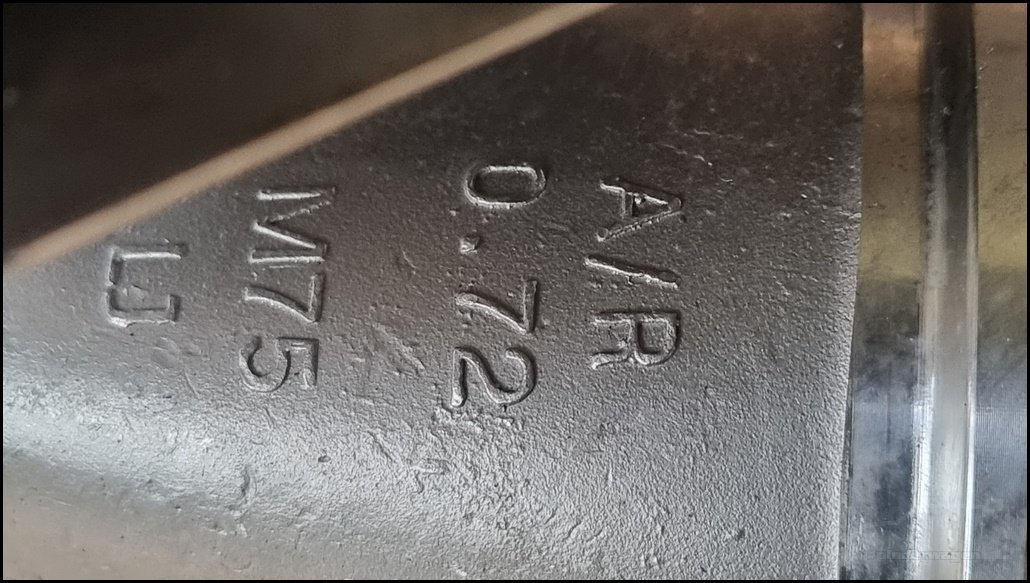

Both use genuine Garrett 0.72 A/R Turbine housings, genuine bearing housing but the Hybrid has a Littco bearing pack.

I`ve fitted an 02Q gearbox over the winter to cope with the increased power. The Quaife gearset kept breaking teeth off gears and was causing too many frustrations on trackdays.

I booked in with Badger5 who are extremely well respected in the VW scene. They sell Littco turbos as people often fit these as an upgrade so they were interested in the results of the testing.

Car in the dyno cell and strapped down. Just enough clearance from the skirts !

I sometimes find that long dyno sessions can cause heatsoak in the fuel system. This will give lean AFR readings so I added a temporary cooler in the return line to the tank. Putting this in a bucket of cold water cools the fuel sufficient to keep the temperature stable. When it warms up simply empty the bucket and refill with cold water.

I run a fuel cooler under the car which works when I`m on track, it`s only the dyno where fuel temp can be an issue.

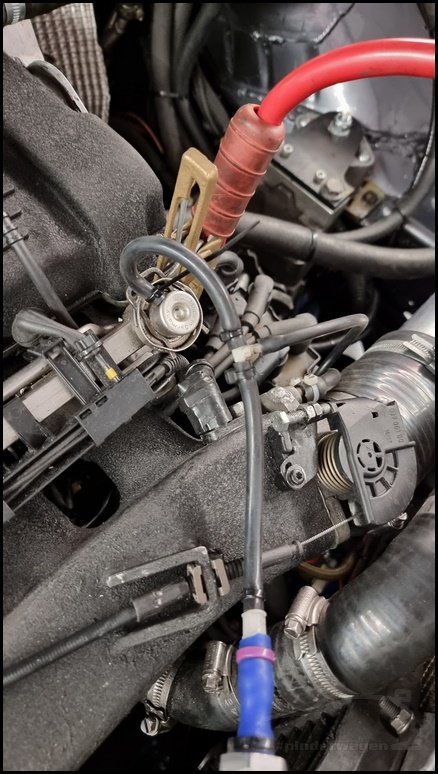

Pressure take off for the Dyno and Jump lead used as an earth to stop static buildup.

Turbo shaft speed sensor. Garrett give maximum shaft speed limit of 165,000rpm and we made sure not to exceed that during testing. I think the peak we saw at 2.1Bar was 159,400.

Knock sensor is the yellow wire at the front of the block, connected to the OEM knock sensor point between Cylinder 1 & 2. Using the one between 3 & 4 can pickup more noise from the gearbox.

With all the sensors in place and the car strapped down it was time to get some baseline data from the Garrett. Bill asked if I wanted to sit in with him and watch what he was doing. I found it very informative but it was pleasing to see I followed his process, I`m just a lot slower doing it.

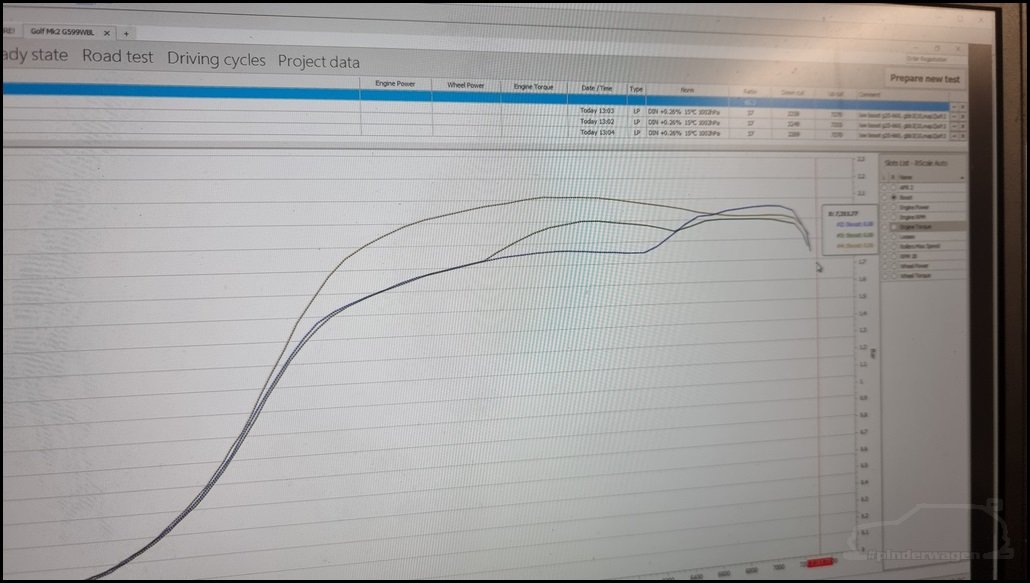

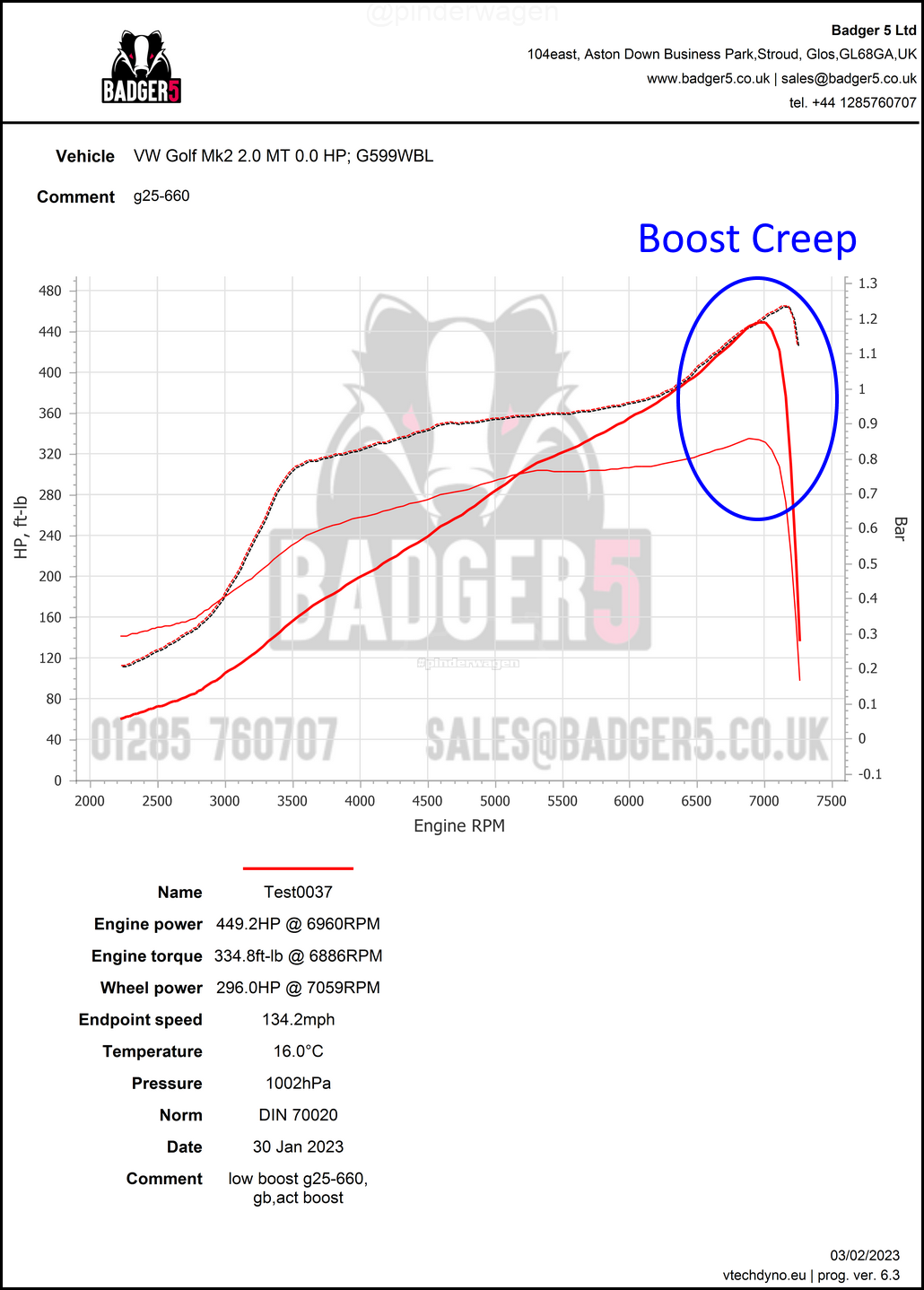

We did several runs but were getting a lot of inconsistencies with no changes to the map. These traces should have been the same.

Protected behind this heatshield is the external wastegate.

I hadn`t nipped up the Banjo to the Wastegate fully and it was leaking from the washer highlighted below. . Tightened it up and we didn`t have an issue for the rest of the day.

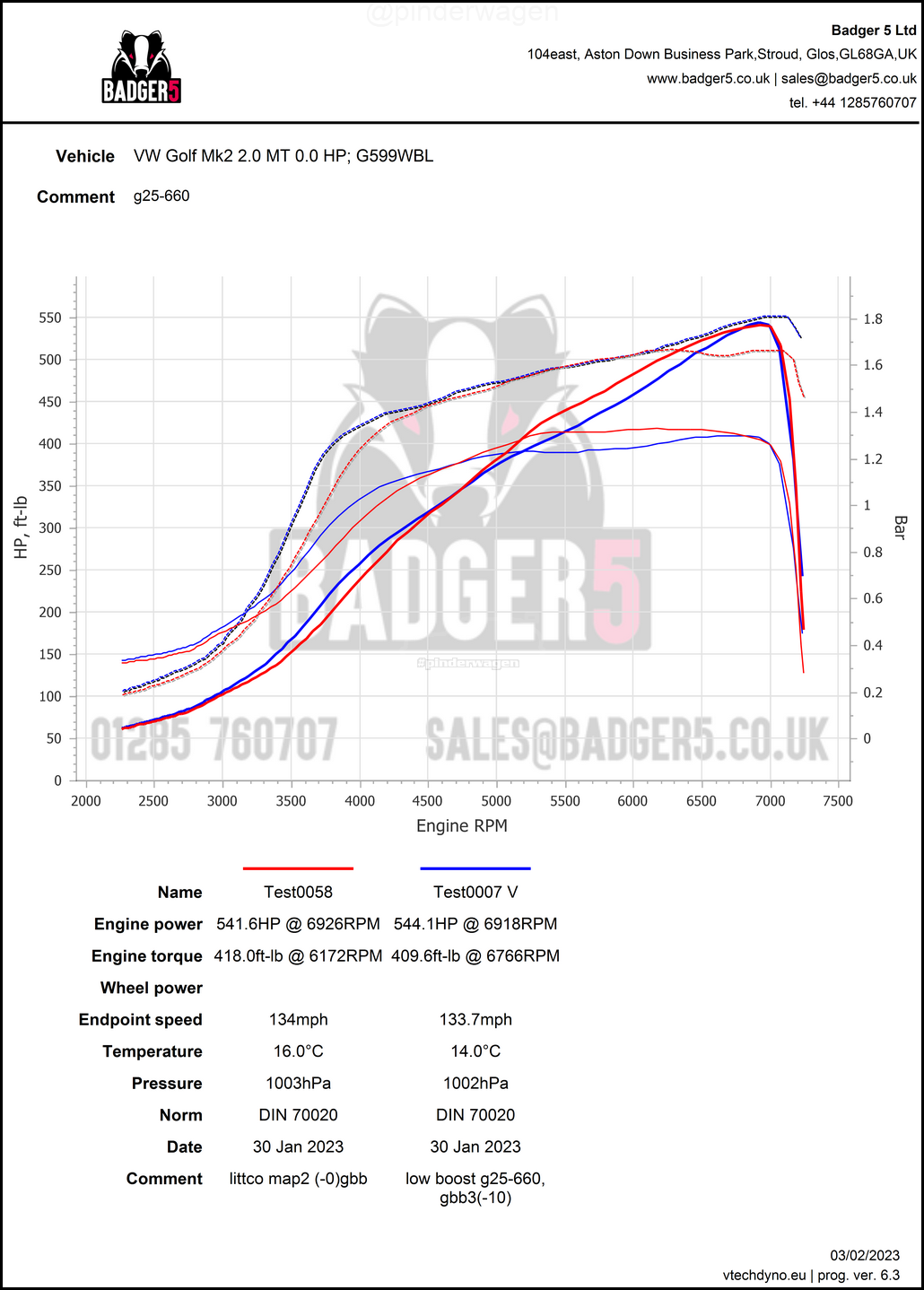

Plots were repeatable after than so we cracked on and recorded all the of required data. Blue run first, then we raised the mid boost wastegate duty to lift the midrange, as expected that was the result and another run confirmed the plots were repeatable. There is zero point in mapping or trying to gather data for a comparison such as this if you don’t have a repeatable platform.

We did many runs at varying boost levels and delivery profiles to get a lot of data on the G25-660 on my engine on this dyno.

My wastegate is 38mm and I always get creep at high RPM as it isn`t large enough for this turbo. This isn`t a problem, I use this creep to lift the high end torque.

G25-660 5th Gear Boost-By-Gear, reaching 1.8Bar at redline. Not rising torque curve.

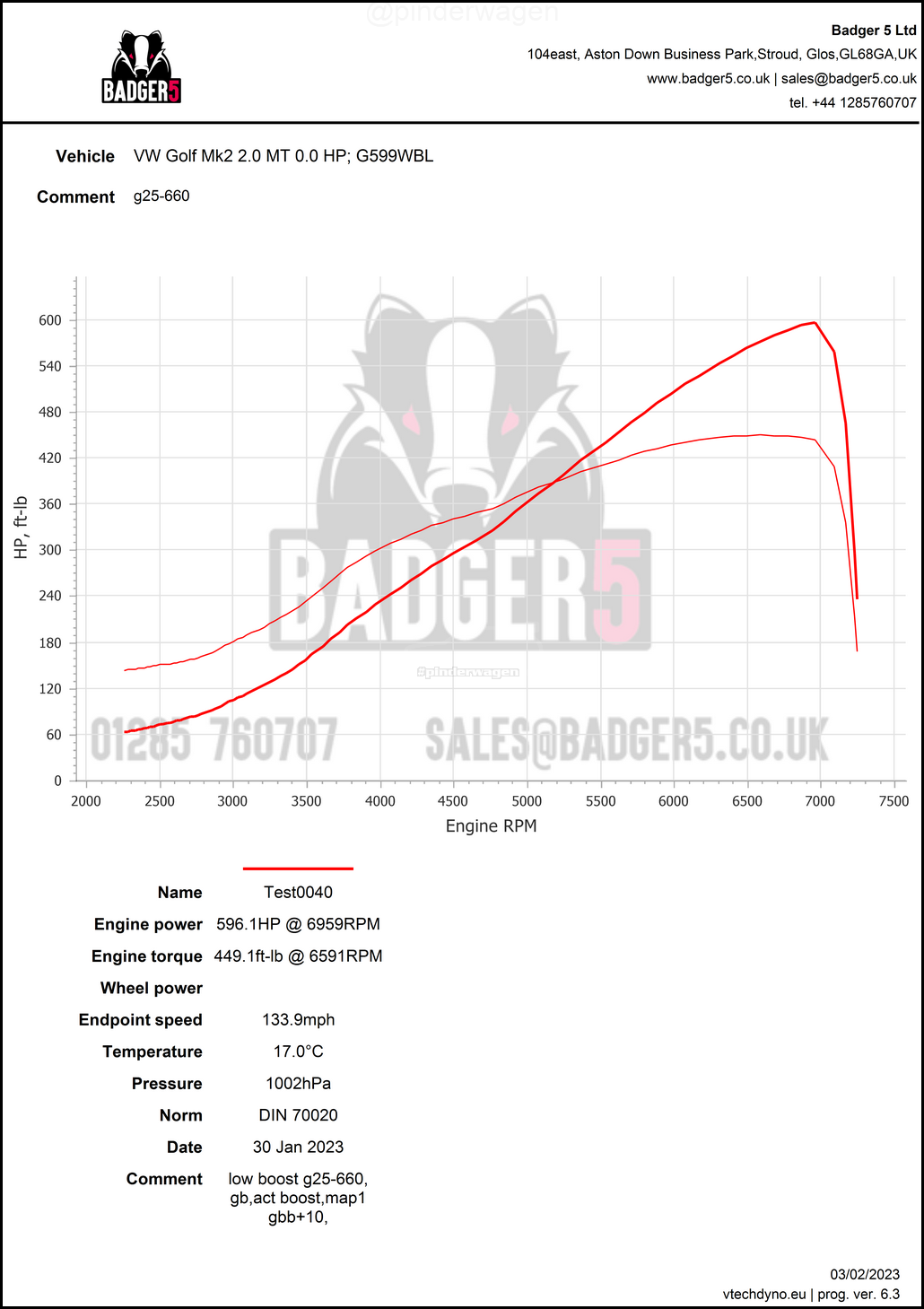

Badger5 often have 20V dyno days, there have been many tuned engines running the 660 and the highest they have previously seen was 585HP on a 2.0 20V with Methanol injection.

We started turning the boost up for high power runs and to say all of us were gobsmacked when we hit 605 HP would be an understatement.

As Bill said ‘That’s 20HP more than we’ve ever seen from a G25-660.’

‘What cams do you have Nige?‘ “Stock ABF road cams”

‘What Headwork ?’ “Stock ABF head, with supertech exhaust valves to cope with the hotter gases. No porting whatsoever”

‘What inlet manifold ?’ “Stock 1.8t 225 BAM welded to an ABF lower half”

It’s an ABF with rods & pistons. We all agreed it simply shouldn`t make this sort of power !

If you looked at the spec of the build and the components used, you`d probably expect it to make between 500 and 540HP. That was what I expected and they thought the same. Nobody was more shocked than us that it produced over 600HP repeatedly.

I did ask, more than once if their dyno was accurate. Both Bill and Alex explained they had cars coming from all over the country and their dyno is once of the more conservative ones. It’s comparable to many other well known dynos and was reading accurately on the day.

By smoothing the curve slightly we ended up with a few HP less but a much nicer slope.

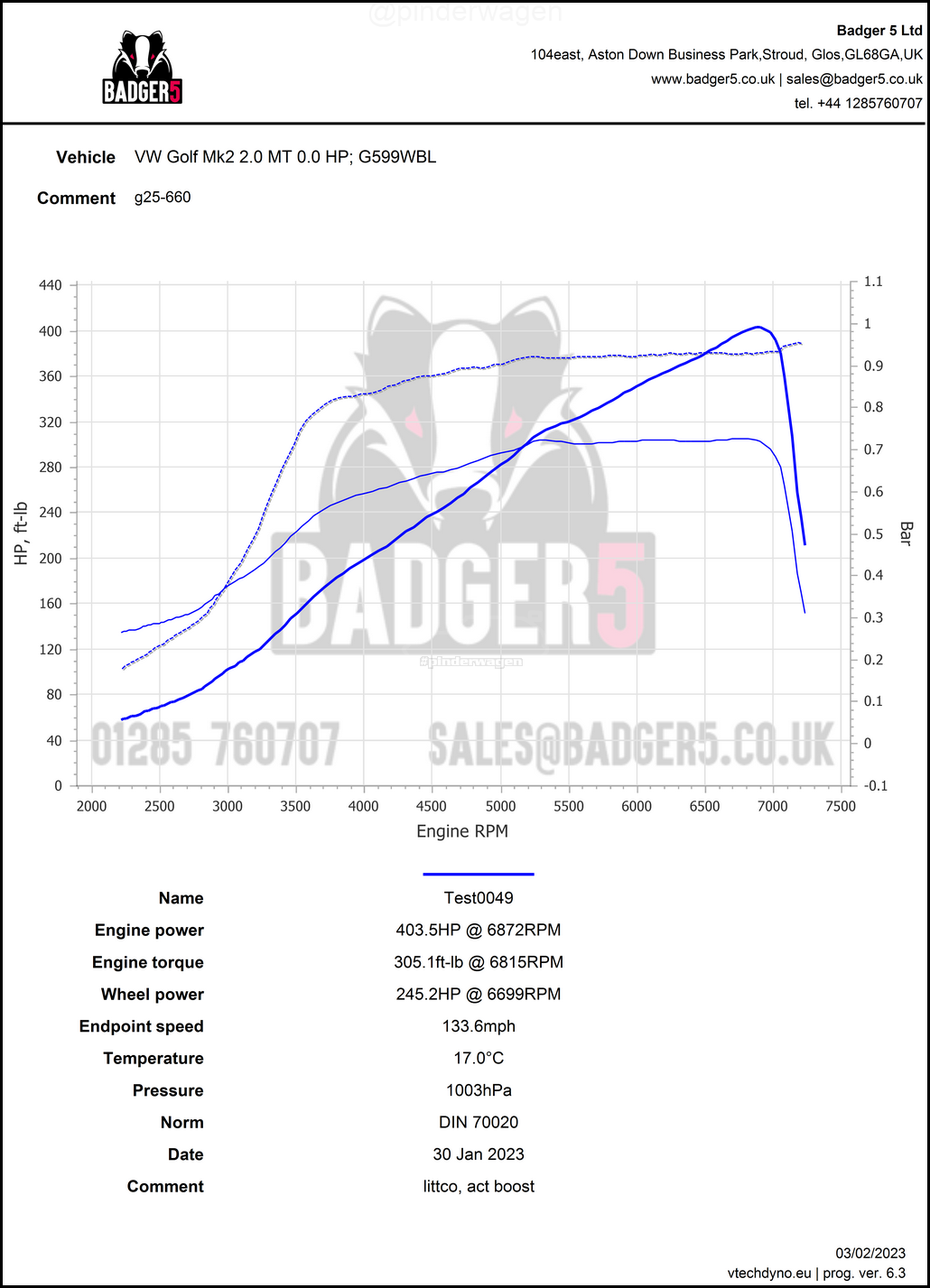

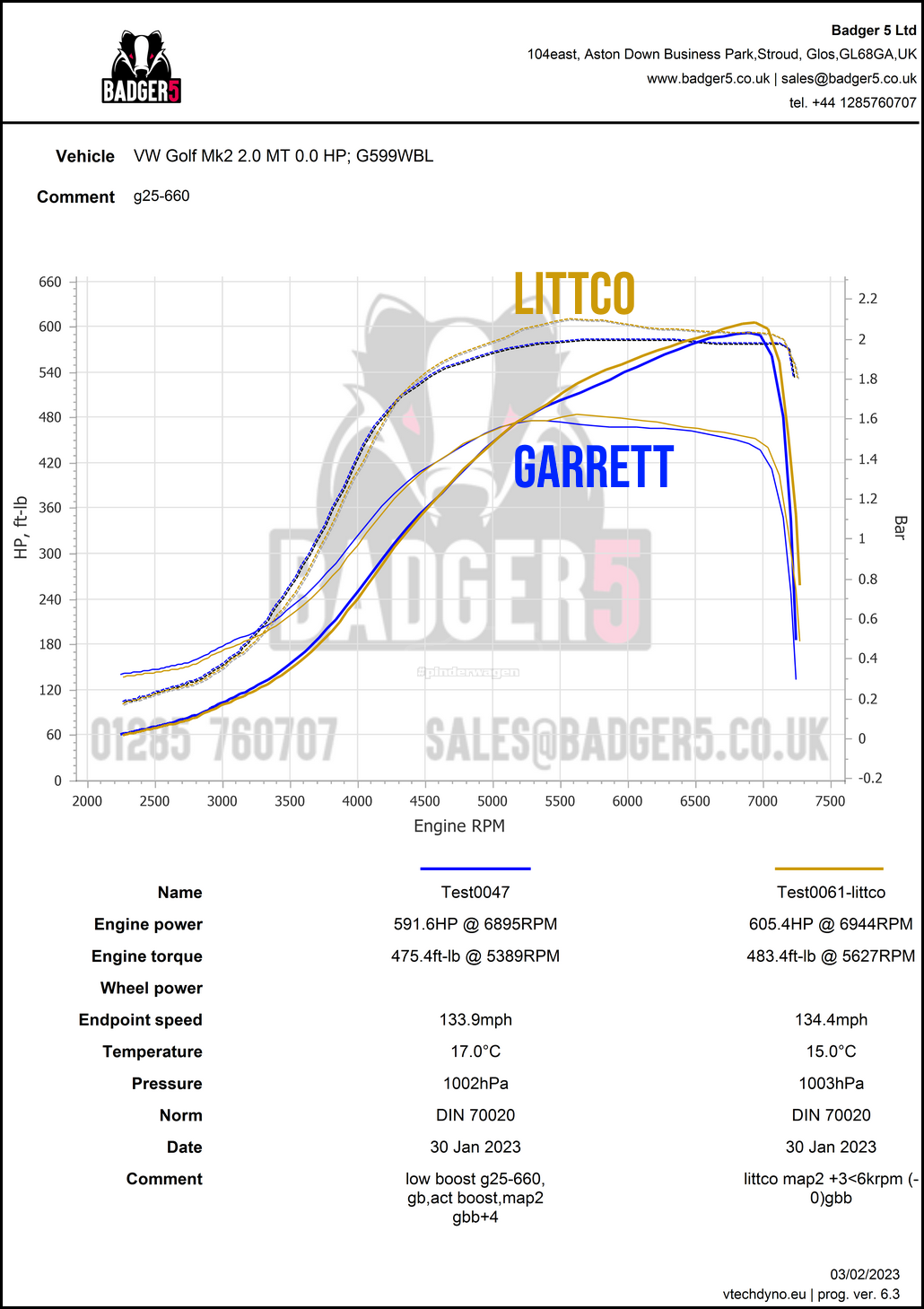

After lunch when everything was cooled I swapped to the Littco. This is the only way to get true back-to-back results. Same car, same dyno, same day. I`m fortunate that with the location of the Turbo, it took 30 minutes to remove the Garrett, fit the Littco and we were ready to go.

First was a simple actuator pull

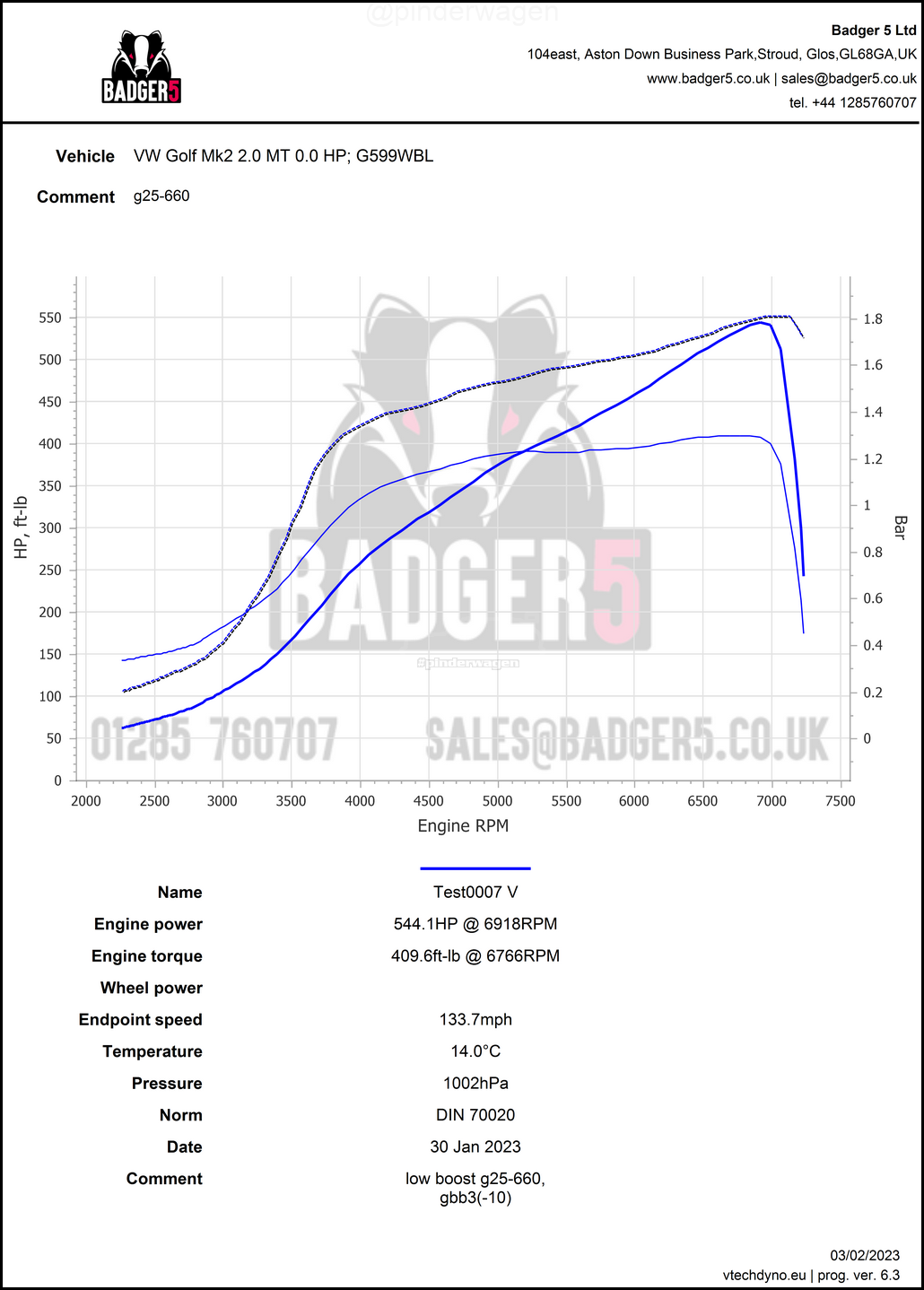

The actuator run surprised us. It was the first time I`ve never had boost creep ! This is a comparison of the Garrett and the Littco on Actuator pressure. Until the Garrett boost starts creeping, the plots are almost identical.

The Littco had no creep at all. It sat at 0.9Bar to redline. This had Bill and I scratching our heads. Bill was the one who worked out what was happening. The new turbine is a bit more restrictive and the boost is backing up in the manifold rather than spinning the turbine faster and making more boost. The wastegate is opening fully and the gases escape through it meaning we don’t get boost creep. If you are suffering from unwanted boost creep, this turbo could be a possible solution.

The Littco needed more duty cycle to generate the boost, this was a pull, then added duty cycle in the midrange and you can see the brown line showing the desired curve. It needed around 15% more boost solenoid duty to make the same boost as the Garrett. Again, this points to a less much restrictive turbine.

The Littco needed around 3% more fuel adding to give the same AFR as the Garrett, a result of it flowing more air. This ties in with it making more power given the same boost level. This is with the boost control solenoid having the same duty cycle, the Littco makes a lot less boost for a given duty. It doesn`t really matter, but I thought it worth including.

This plot shows it nicely. 5th Gear Boost-by-Gear. Note the Littco (RED) makes more midrange with the same boost level, allowing us to drop the peak boost by 0.175Bar and still make the same power and torque.

From 5000 to 6500 on the same boost as the 660, the Littco makes more torque.

Bill, Ash (who called in to see Bill), Luke & Alex chatting between sessions. What a great bunch of guys !

Both Turbos in 6th Gear Push-to-pass. The Littco is running slightly more boost here which helps maintain the high level of torque until redline.

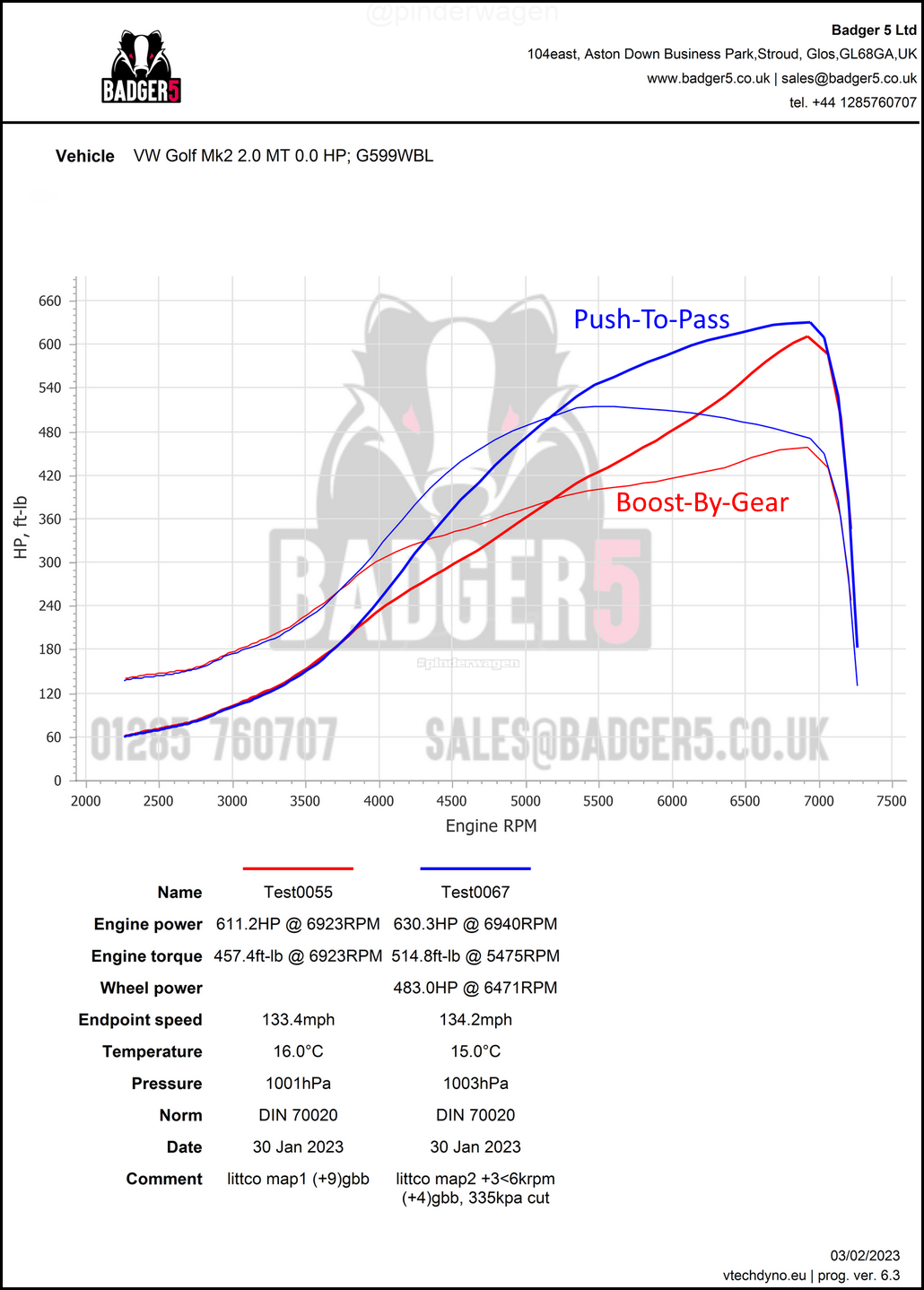

Once we had the mid boost pulls and everything setup we started winding up the boost. We did a 618HP pull, added some timing which saw 639HP although Bill detected some detonation so we went back to the previous safe ignition map. Did another run which hit the boost cut at 2.2Bar.

Bills said “I just need to drop the boost duty table slightly, we hit the boost limit”

My reply was simple. “Bill, don`t lower the boost, just lift the limit”

He gave me a look  . Asked if I was sure. I was so we lifted it to 2.3Bar and did another pull which peaked at 2.25Bar.

. Asked if I was sure. I was so we lifted it to 2.3Bar and did another pull which peaked at 2.25Bar.

Thats just ridiculous. My Golf produced over SIX HUNDRED horsepower !

If you recall my comment earlier in this post, the idea was to see if the Littco could maintain torque at high boost & rpm compared to the Garrett, the answer is a definite YES.

The highest run of the day with no issue was 630HP @ 6940rpm. Producing a peak torque figure of 514 ft-lb @ 5475rpm. More pleasing was the shape of the torque plot, it is over 480 ft-lb from 4920rpm until 6,800rpm.

Following on from this dyno session, Bill had another car on the dyno with the same Turbo. They found inconsistencies with my data and realised the clutch wasn`t fully disengaging on the coastdown. The WHP values are correct, but the calculated Flywheel figures aren`t due to clutch drag on coastdown.

Usually the gearbox would be put into neutral after the pull but the Sequential shifter doesn`t allow that.

Rather than 630HP, a more realistic Flywheel figure is 560-570HP with 483WHP. Which is still absolutely amazing !

I didn`t leave until after 19:00. Whilst it`s certainly not something they do often, Bill, Alex and Luke worked after ususal closing time to get the runs completed. Thats why they are so well respected, they go that extra mile to help the customer when they could have said “that’s it, we need to get home”

Am I happy ? I`m absolutely gobsmacked at the Golf reaching over 600hp repeatedly. This wasn’t a fluke, it did it again and again.

Boost by gear will be the same as previously, ranging from 400HP in 3rd to 600HP in 6th with a linear torque plot like this one.

I often talk about the Boost-by-gear and Push-to-pass. These are accessed by a button on the steering wheel. This graphically shows the difference. Both make almost the same power but the PTP map has a huge increase in torque in the midrange. I deploy this when on the straights, it overwhelmes the front tyres otherwise.

Just think about that for a moment. At 5,500rpm I`m making 425BHP and 400 ft-lbs. By simply rolling my thumb and pressing a button that jumps to 550HP and 510 ft-lbs in less time than it took you to read this.

I`m joking !!  I won`t be running 600HP on Boost-by-gear. It`ll be from 400 to 500HP with the same shaped delivery

I won`t be running 600HP on Boost-by-gear. It`ll be from 400 to 500HP with the same shaped delivery

I WILL be turning it down, its just too much. I’m still only FWD, run 235 section tyres and even with boost by gear, that’s putting a huge amount of stress on everything. Even knocking it back to the previous 500HP in 6th is plenty!

We did 67 dyno pulls through the day. More than Bill has every done on one car in one sitting. Nothing broke. Nothing overheated and we just kept doing run after run. It really does give me a lot of confidence in the build.

I’ve spoken to Dan at Littco about the results. He has another car that is being tested on the Badger5 dyno in a couple of months that had a G25-660 fitted before and I`ll update this post with more plots from that test.

If you have a G25-550 or a damaged 550 or 660, this Hybrid would make a brilliant upgrade. From a stock 660, I`m just not sure it`s worth the change. It does give another 25HP peak and 15-30 midrange boost for boost, but at the loss of 150rpm on initial spool. I am on track in a couple of weeks and I suspect the loss of response will be negligible and not something I`ll feel from the drivers seat.

I`ll finish off with the highest power run we had. Littco G25-660 Hybrid. 2.25 Bar midrange dropping to 2.1Bar peak.

630HP and 514 FtLBS. Bonkers !.