Whilst I think the R8 looks great on the 19″ wheels, the availability of track tyres is limited. Those that are available are expensive, and I want to run slicks. More specifically, I want to run used slicks. New slicks are £300+ each; I can buy lightly worn used ones for approximately £50 each. Race teams run them for a race, then replace them. So yes, they are past their best in terms of grip, but they are still perfectly acceptable to use on trackdays. New R tyres, ie A052, CR-S, DZ03 are similar money to new slicks. As the largest consumable, especially with a heavy car like this is tyres and brakes (as well as fuel, but let’s not even go there !), being able to run used slicks will mean a huge saving going forwards. I ran them on the Golf for many years.

I am not chasing tenths, so running a tyre that is slightly past its best is not a concern. Running a set of tyres that costs £200 vs £1400 is far more of an issue.  We could have a long debate about used vs new track tyres, slicks vs semi slicks, and so on. Personally, I find used slicks are as good as new semi slicks. The slicks last longer, and by that I mean in terms of heat. As there are no tread blocks, the rubber does not move around as much on the tyre, which builds less heat. After two laps of the Ring, you can feel a semi slick starting to drop off. The front end is not quite as precise, and turn in is just a little bit lazier. They are still perfectly adequate, and a bit of tyre management helps, but once you compare that to a slick where you can easily do three laps with almost no drop off, you see the attraction.

We could have a long debate about used vs new track tyres, slicks vs semi slicks, and so on. Personally, I find used slicks are as good as new semi slicks. The slicks last longer, and by that I mean in terms of heat. As there are no tread blocks, the rubber does not move around as much on the tyre, which builds less heat. After two laps of the Ring, you can feel a semi slick starting to drop off. The front end is not quite as precise, and turn in is just a little bit lazier. They are still perfectly adequate, and a bit of tyre management helps, but once you compare that to a slick where you can easily do three laps with almost no drop off, you see the attraction.

That is before factoring in the cost, and the fact that slicks simply feel nicer. The turn in is sharper, the rubber does not roll when you turn the car into a corner, and there is less delay between turning the steering wheel and the car reacting.

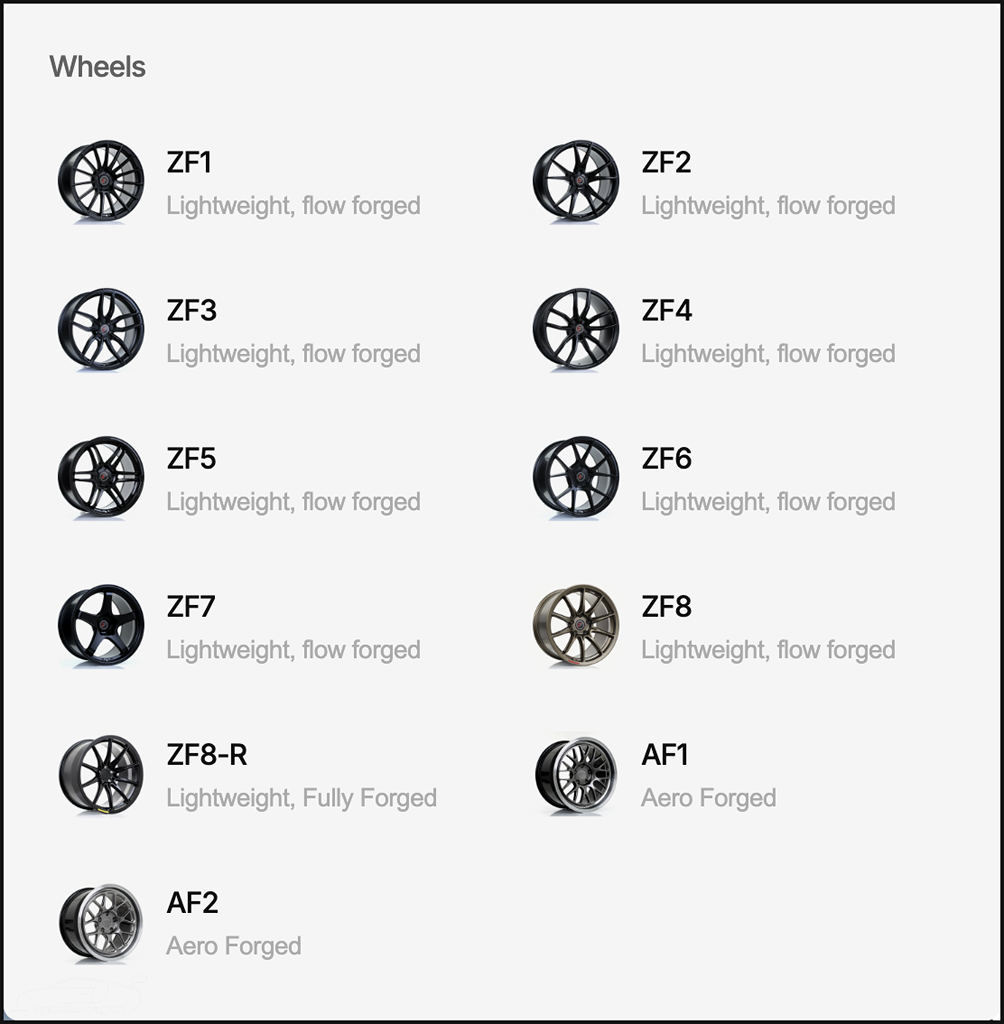

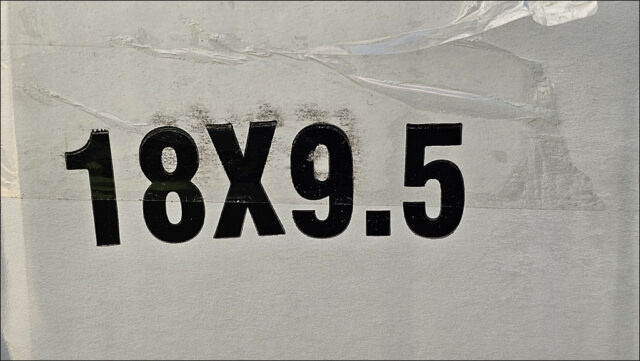

Bearing all that in mind, I needed some 18″ alloys. Back in the day, Team Dynamics Pro Race 1.2 were the ones to go for. They struck a good balance between cost, lightness, and design. Nowadays, 2Forge have taken that place. They have a great range of wheels. I was tempted to go with the ZF5, which is very similar to the OEM 5 spoke V8 alloy, but in the end I settled on the ZF6. The go-to seems to be the BBS E88 wheel. Whilst it might be an unpopular opinion, I simply do not like the E88 wheels. They are expensive, I’m not a fan of the styling and although many people seem to love them, I have never quite understood the appeal.

2Forge do not sell directly to the public; you order through one of their retailers. I use swiftperformance.co.uk, who are BMW specialists and lifetime sponsors of Destination Nurburgring, so even though I do not have a BMW, I know them very well.

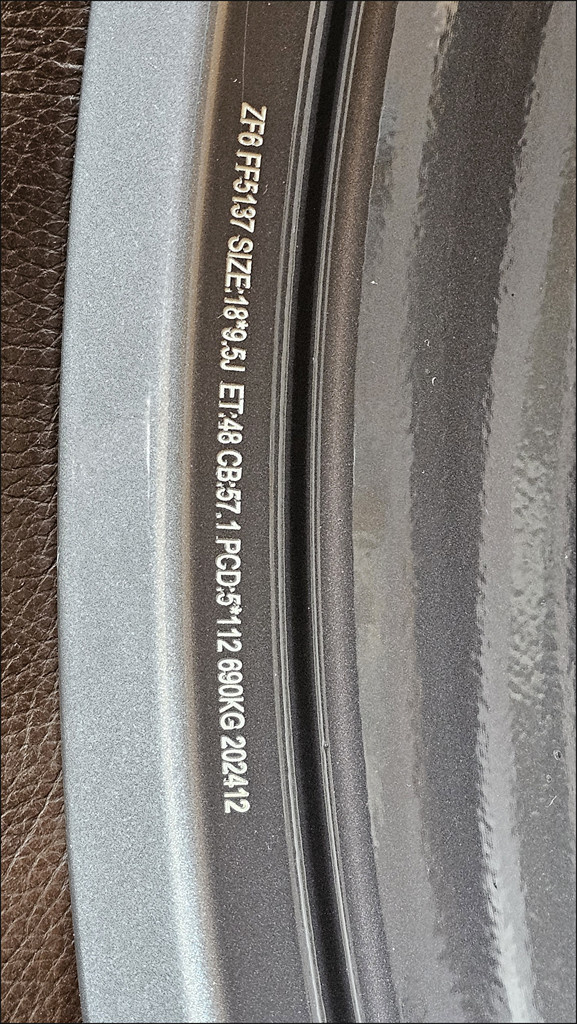

Actually measuring the standard wheel, then working out the offset I wanted took some time, but I settled on the following.

Front: ZF6 Gunmetal, 9J x 18″, 5 x 112, ET42, centre bore 57.1mm

Rear: ZF6 Gunmetal, 11J x 18″, 5 x 112, ET46, centre bore 57.1mm

A few days later they arrived. The reason they arrived so quickly is that they are stored as pre coated blanks. What I mean by that is the wheel is already finished, but the centre bore, ET, and PCD are machined once they are ordered. So you could not order a 4 x 100, for example, it has to be somewhere between 5 x 98 and 130. The amount of material allows a large range of offsets to be machined.

This means the taper for the bolts is already clean, no powder coat to remove before you mount the wheels. You can see the extra material allowing the machining of the desired PCD. I never notice it when the wheels are mounted, but if it is a big deal to you, I suppose you would order some much more expensive custom wheels.

I immediately coated them with a ceramic coating to try and protect them from the inevitable brake dust. They will never look this clean again, that is for certain.

The 255/35R18 A052s sit nicely on the 9J. I would have preferred a 9.5J, but they do not list one.

Even though they do not quite fill the arches, I think they still look great.

Then I went to Spa and through one of those coincidences of this small trackday world, I met Julian. He is the owner of 2Forge, and he commented on the wheels on the R8 and that I had tagged them on Instagram. I was discussing what I like about them and also raised a couple of areas I would prefer to see tweaked. The barrel around the nut for the socket is too small; you need a slim socket, and if you have one of those alloy safe ones with the plastic sleeve, you need to remove the sleeve. He was aware of that and said it is something they are looking at, but it means completely re tooling the machinery.

The second thing I mentioned was that I would have preferred some 9.5J. I simply cannot fit 10J under the standard arch on the R8, but 9J was just that little bit too small for the 255 A052s and 265 slicks. We had a good chat, and he said they could make a custom set if it would help. I was very interested and after a few discussions by email a set was order through SP again. The lead time was obviously longer, it ended up being a couple of months, but I eventually received a pair of 9.5J ZF6’s

The big benefit of being completely custom is the rim is made for 5×100, so the larger blank for the 5×98 to 5×138 is replaced with a 5×100 casting.

One-off pair of ZF6

With 255/35R18 A052’s you can see the sidewall on the 9.5J has that slight ‘stretch’ which translates to a noticeably sharper turn in. Whilst the A052 are superb track tyres, the sidewall is a bit on the soft side compared to Direzzas for example. On the 9J, they were rolling over a bit more than ideal and I could feel that from behind the wheel. The wider rim gives that little bit more support and whilst the soft sidewall is still there, initial turn-in is improved and mid corner understeer slightly reduced.

A very worthwhile improvement, the only downside is at full lock, the inner rim of the wheel touches the coil of the spring. It’s only at the very extreme of lock and even then it just touches. It’s never too much to be an issue even if I had a moment and needed full lock to recover, but it has scuffed the spring and inner edge of the rim slightly.

After a year of abuse, the wheels have held up extremely well, the corners between the spoke and the outer rim and sharp which makes cleaning embedded brake dust a pain, a larger radius would be nicer but that’s not a biggie on track wheels. The centre bore is large and the rims are supplied with aluminium spigots to fit the desired hub. I keep meaning to tack these in place, I’ve lost count of the number of times I’ve fitted a wheel witout one, or removed the wheel and the spigot has rolled under the car